Organization description:

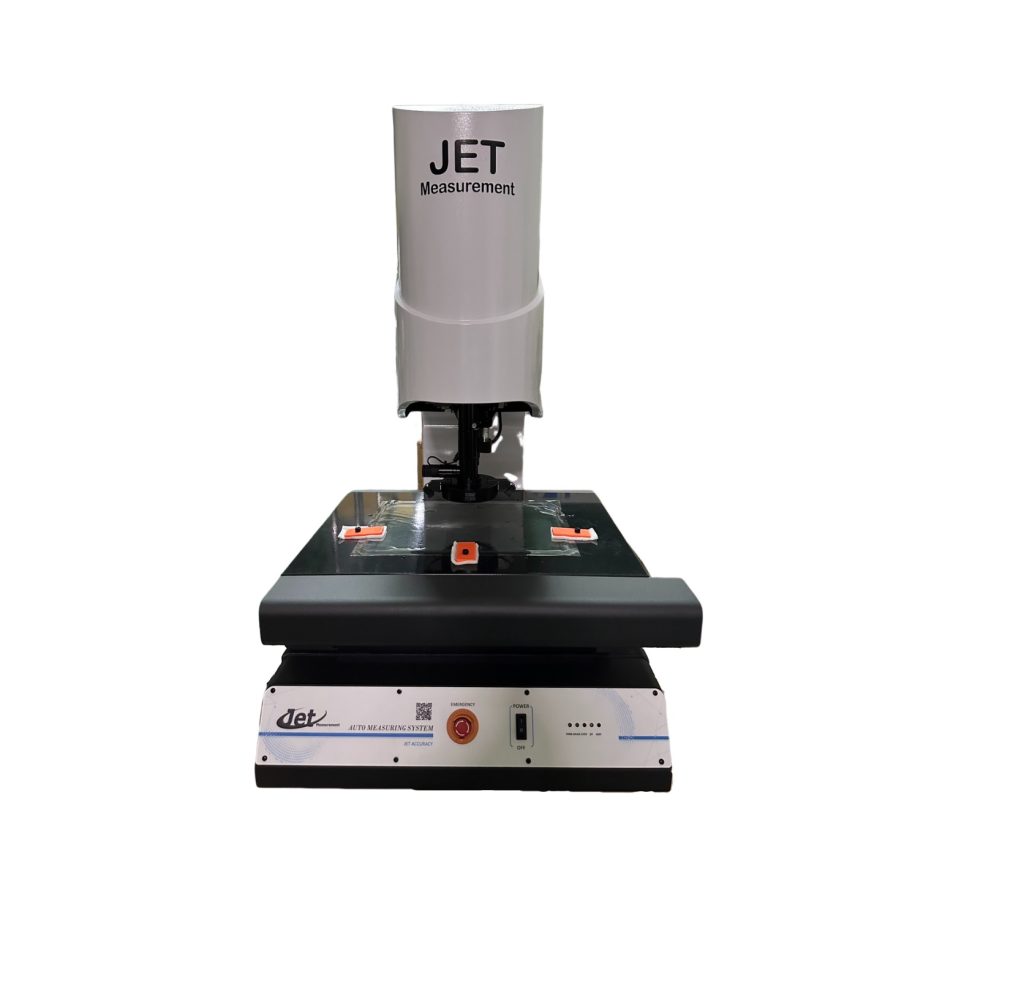

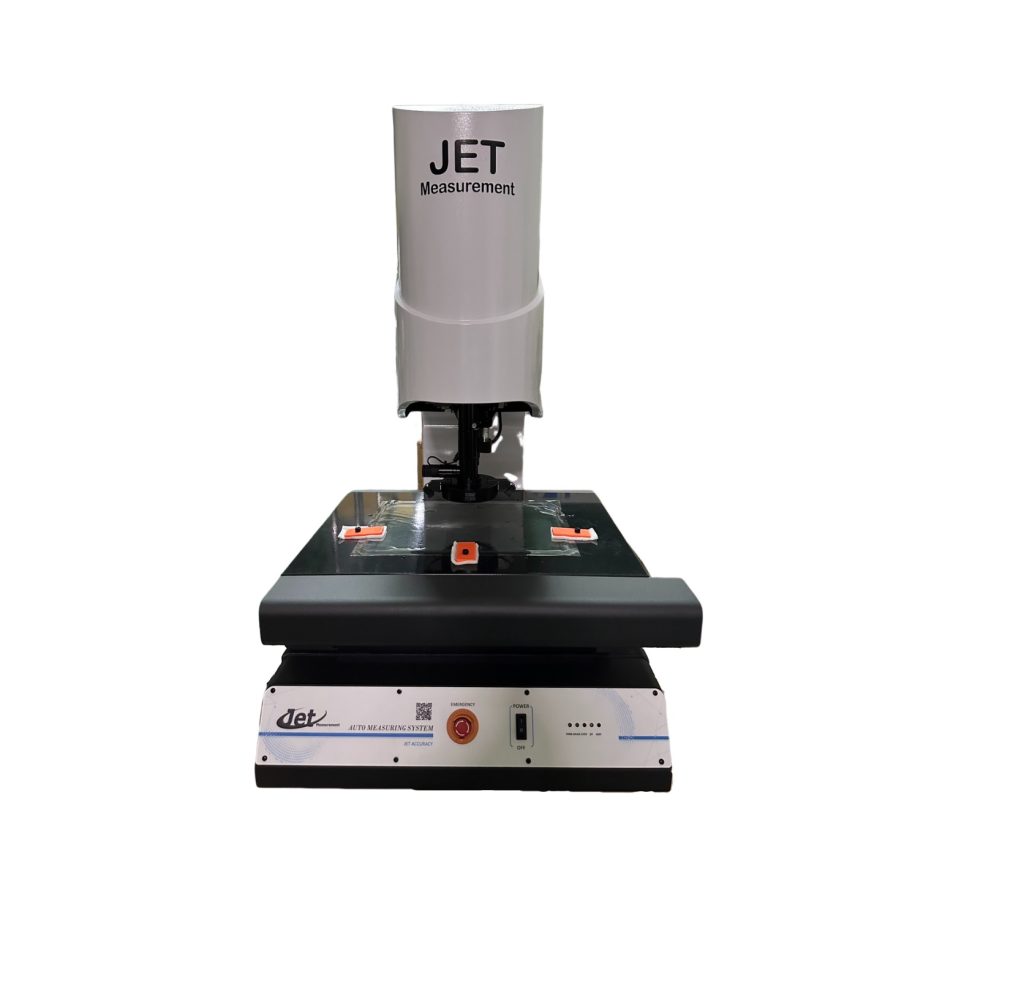

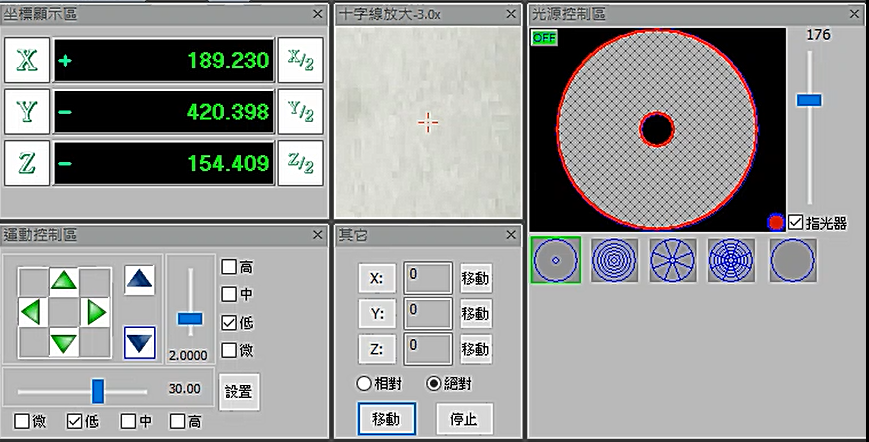

1. MIT image measuring instrument made in Taiwan

2. Precision grade granite mechanism

3. The XYZ three axes are driven by Panasonic servo motors

4. Adopt grinding grade crossed roller linear guide

5. XY movement measurement accuracy±0.003mm

6. Measurement reproducibility accuracy±0.001mm

Light source matching:

<Image measurement>The definition of is very simple, as long as"If you can see it, you can measure it."

The lighting of the light source system is also a very important part! ! !

Lighting system:

- LED multi-segment surface ring light

- LED point coaxial light

- Telecentric LED backlight (green light)

- External coaxial LED light source (optional)

- Laser indication point search (macroscopic search for measurement position)

Optical lens:

Standard with continuous zoom telecentric lens 0.7-4.5X (optional manual lens)

The total magnification can reach 23X-148X, FOV: 11.1-1.7mm

It can be equipped with a metallographic objective lens to increase the magnification and observe smaller structural measurements.

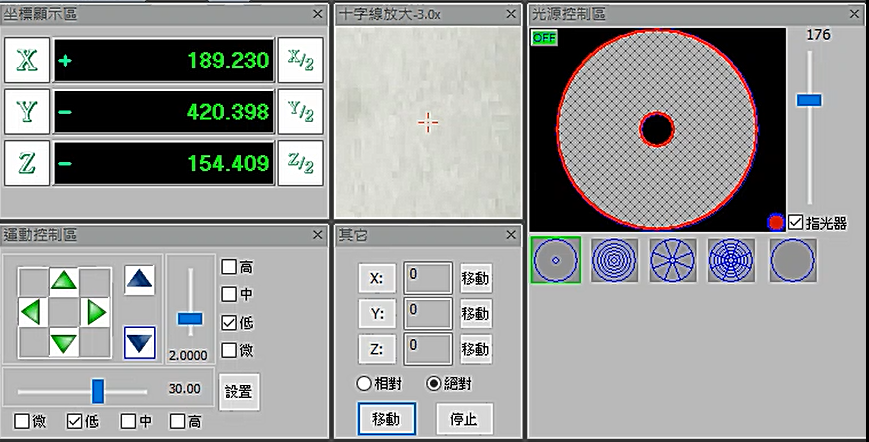

Operation interface:

Movement direction control and light source settings can be intuitively selected and recorded in template writing

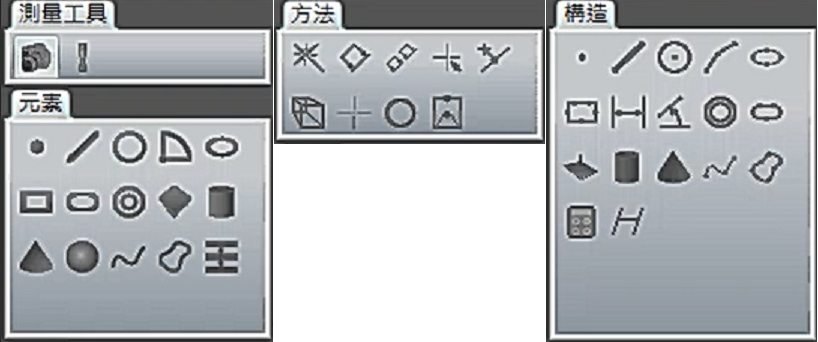

Measuring element functions:

Various measurement elements can be clicked to operate.

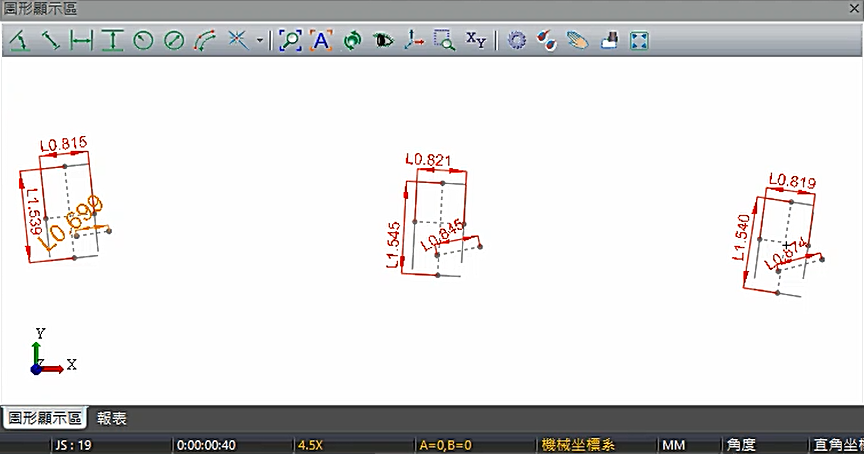

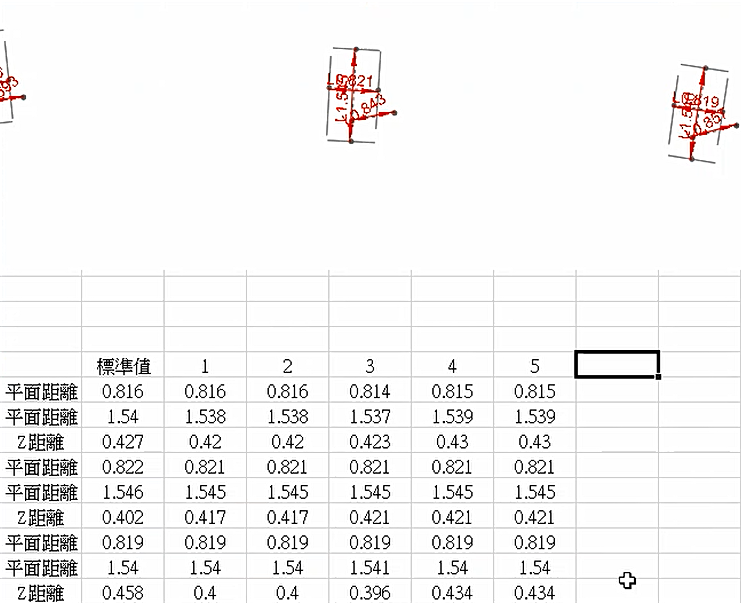

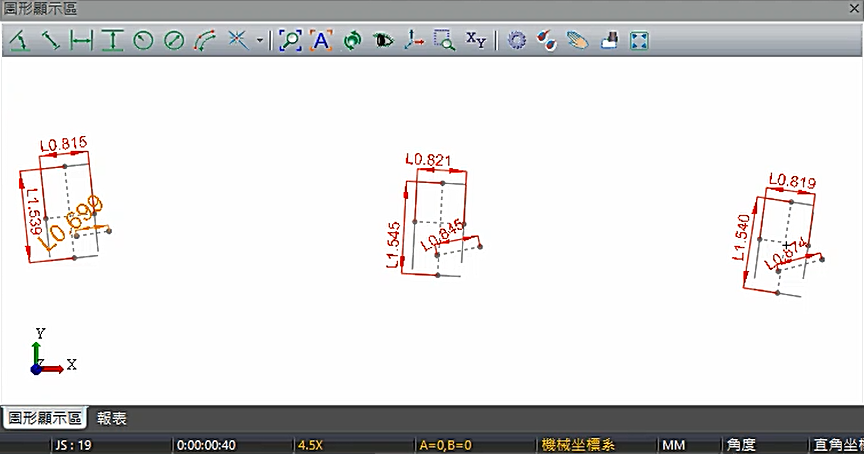

Operate the drawing area display, observe the measurement data in real time, and can export and save CAD files

You can also import CAD files for comparison

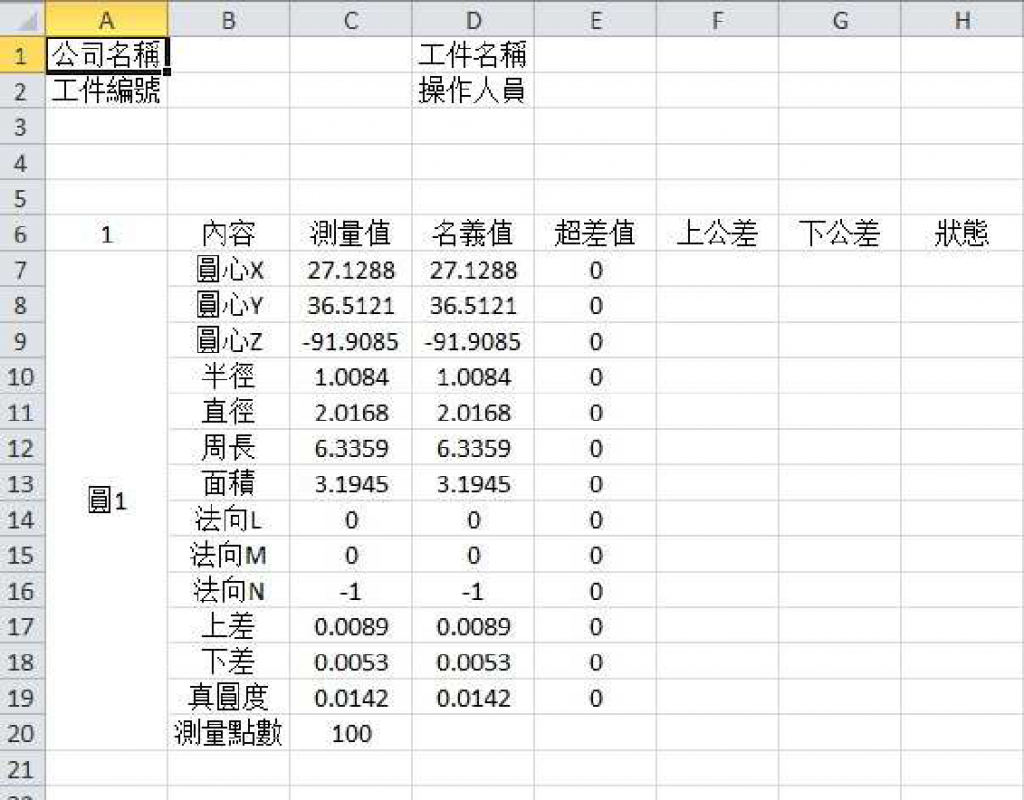

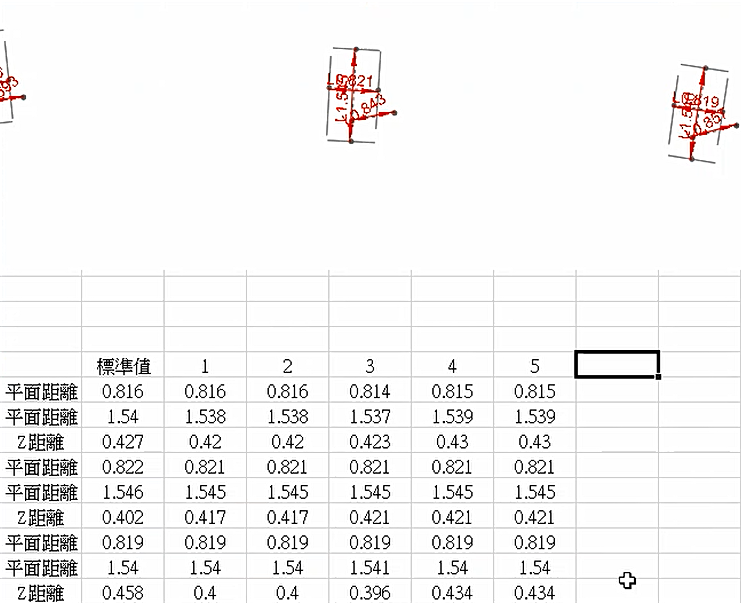

Data report export, multiple built-in report types can be selected and used

You can also customize the report export format

Our company independently develops automatic image plus probe and laser displacement measurement application software, which can perform visual analysis, processing and detection of two-dimensional measurement coordinates.

Probes can also be used to measure three-dimensional geometric elements, or laser displacers can be used to measure flatness and height. Used in various precision manufacturing industries,

Such as: mobile phone components, molds, electronics, communications, machinery, hardware, plastics, instruments, watches, PCB, LCD and other industries. Measurable materials include metal, plastic, rubber, glass, PCB, ceramics, etc.;

1.Measurement of geometric elements

It can measure fifteen kinds of geometric elements (points, straight lines, planes, circles, arcs, ellipses, rectangles, keyways, rings, cylinders, cones,

sphere, open curve, closed curve and focal plane), and can measure height and preset basic geometric elements.

Features:

(1). According to the actual measurement needs, you can choose contact measurement-probe measurement, or you can choose non-contact measurement

—Image and laser displacement measurement.

(2). Multiple measurement methods: intelligent edge finding, overall point collection, multi-segment point collection, mouse point collection, adjacent point collection, cross line point collection,

Enlarge the sampling points, compare the sampling points, probe sampling points and laser sampling points;

2. Geometric element construction

Powerful geometric element construction function, which can construct two-dimensional and three-dimensional geometric elements;

Features:

(1). A variety of elements can be constructed: such as points, straight lines, circles, arcs, ellipses, rectangles, distances, angles, rings, keyways, planes,

Cylinders, cones and spheres;

(2). Multiple construction methods: extraction method, intersection method, perpendicular method, parallel method, tangent method, symmetry method, mirror method, etc.;

3.Coordinate system

It can establish the mechanical coordinate system and the workpiece coordinate system, realize the coordinate transformation of each coordinate system, and can easily realize the direct coordinate system.

The mutual conversion between the angular coordinate system and the polar coordinate system enables the storage and use of each workpiece coordinate system. You can establish two-dimensional coordinates or three-dimensional coordinates;

4. User program

Unrestricted user program recording, editing, saving, and recall functions. The QMS3D user program can

Record and edit all user actions to achieve copy measurement and greatly improve measurement efficiency.

Simple user program teaching method, you can copy the teaching steps, powerful visual editing function, convenient

Batch testing.

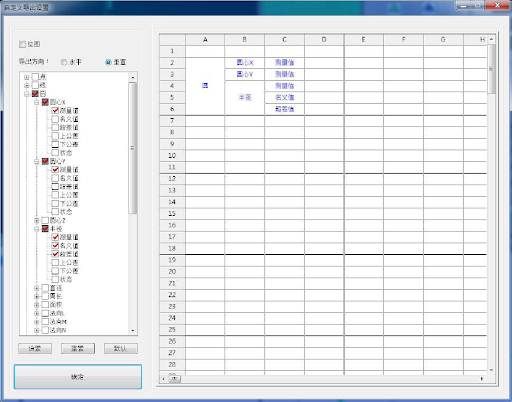

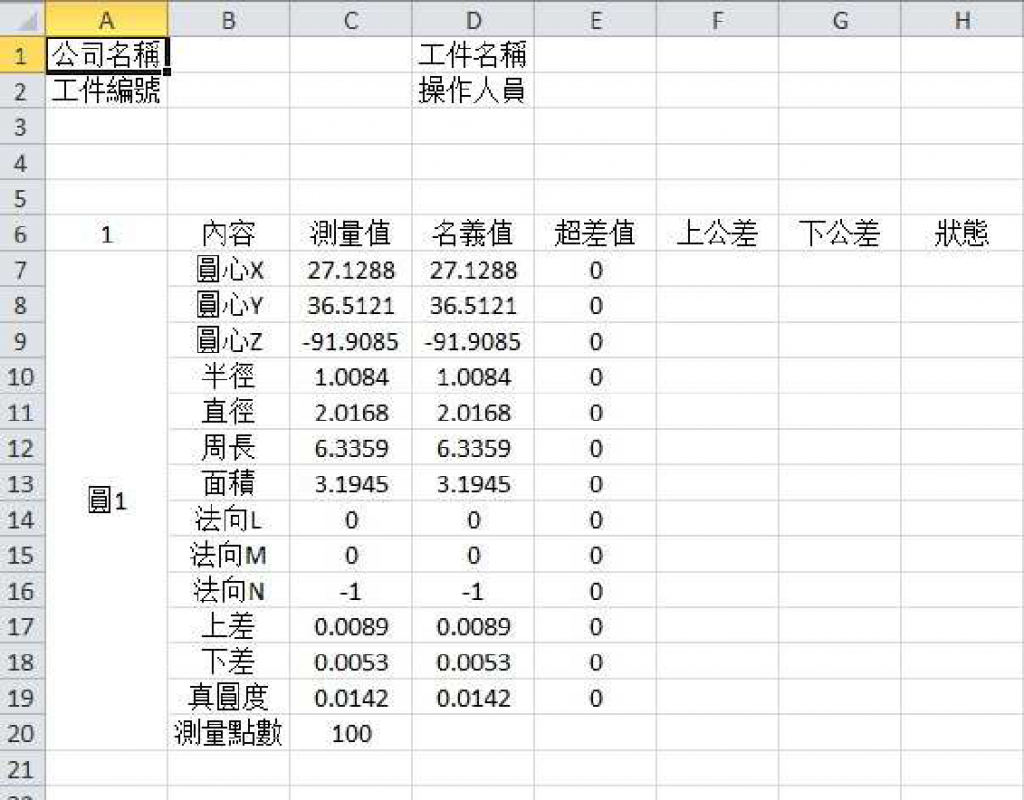

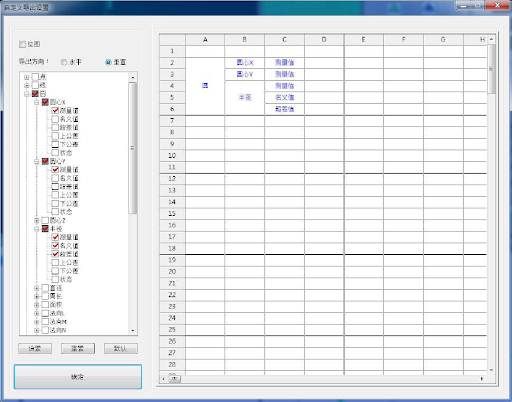

Multiple report export formats

You can set the exported content of elements, the export direction, and whether to export bitmaps.

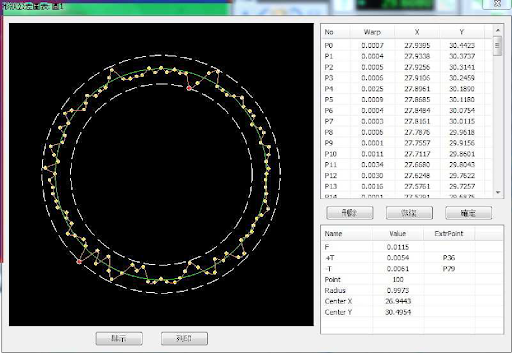

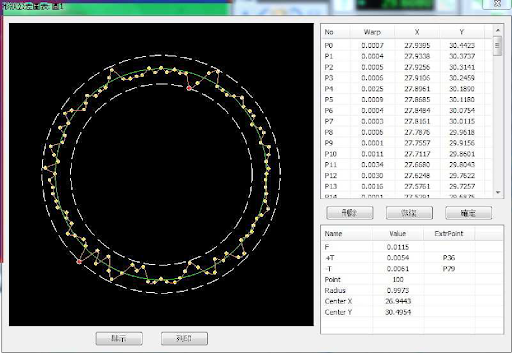

Geometric tolerance measurement

Shape Tolerance Chart:

Measure the shape tolerance charts of straight lines, circles, planes, cylinders, and balls. You can delete measurement point errors as needed.

If the difference is large, you can print the shape tolerance chart of the element and view the shape tolerance attributes.