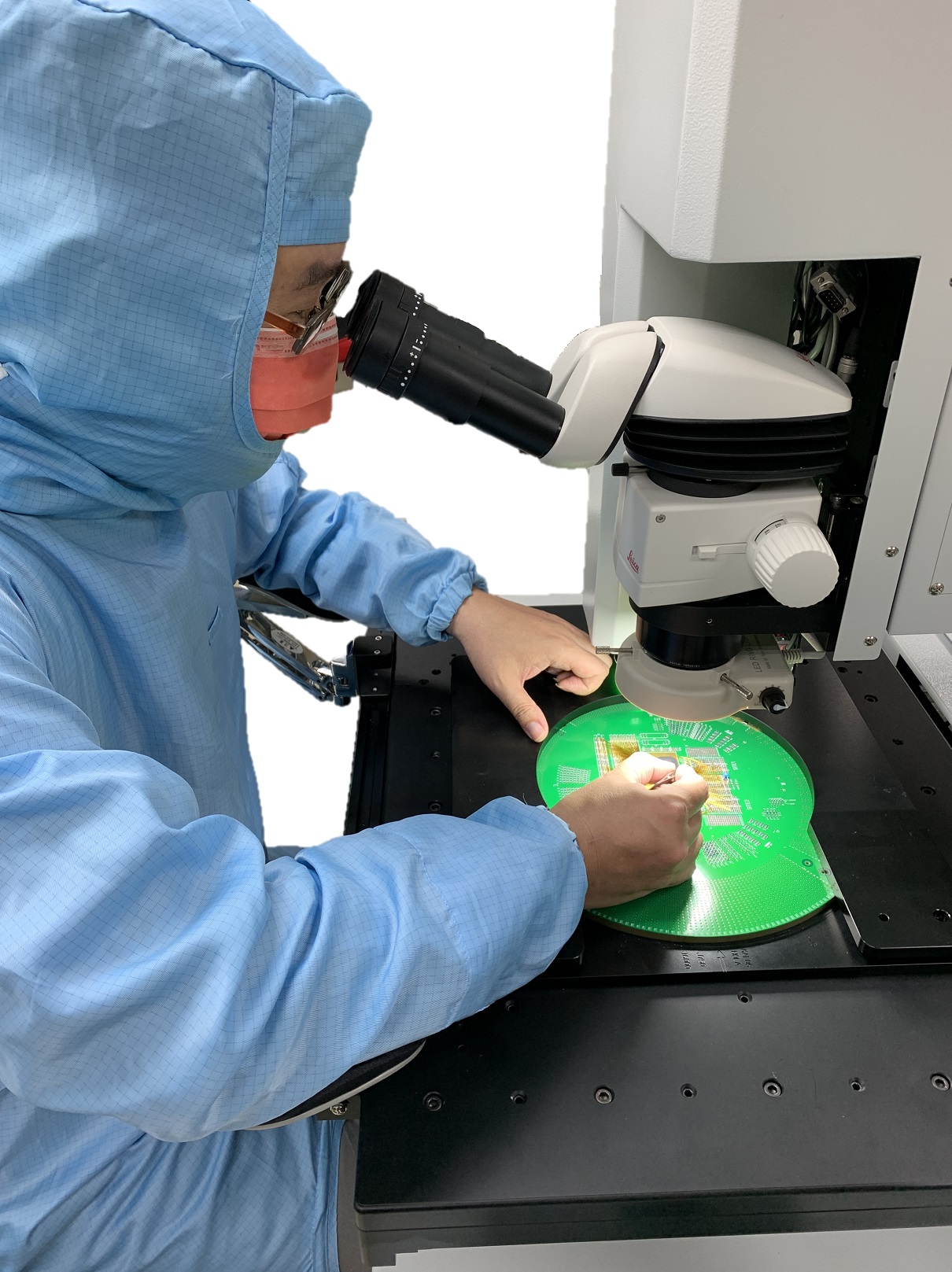

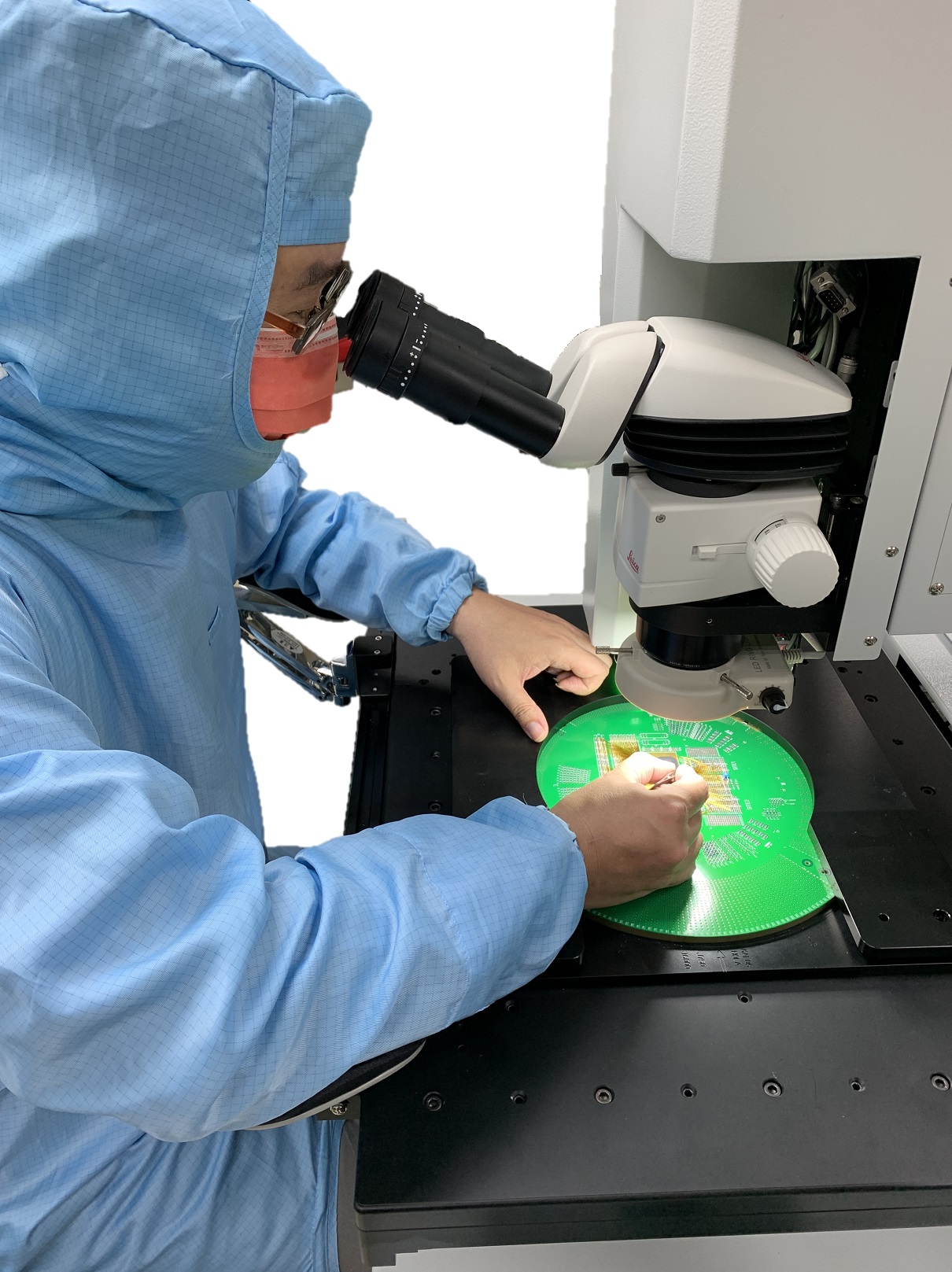

The biggest advantage of this equipment is that the maintenance time of the auxiliary inspection personnel in the probe card is greatly reduced, and the product quality is stable.

The method of programmed setting can quickly carry out IQC incoming inspection, and inspect the quality of outsourced probe cards to effectively improve production efficiency.

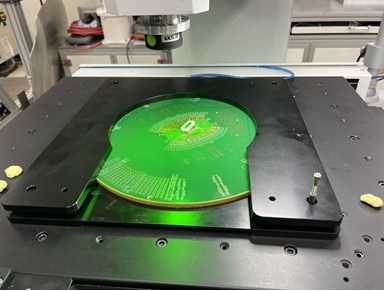

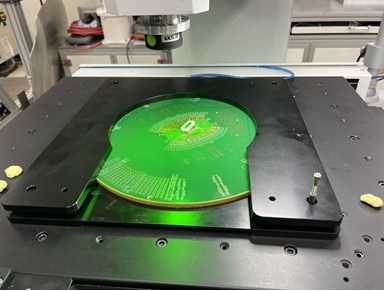

The ten-card fixture has been designed and specified, and each positioning point has a Probe card number, which is convenient for personnel to operate horizontally

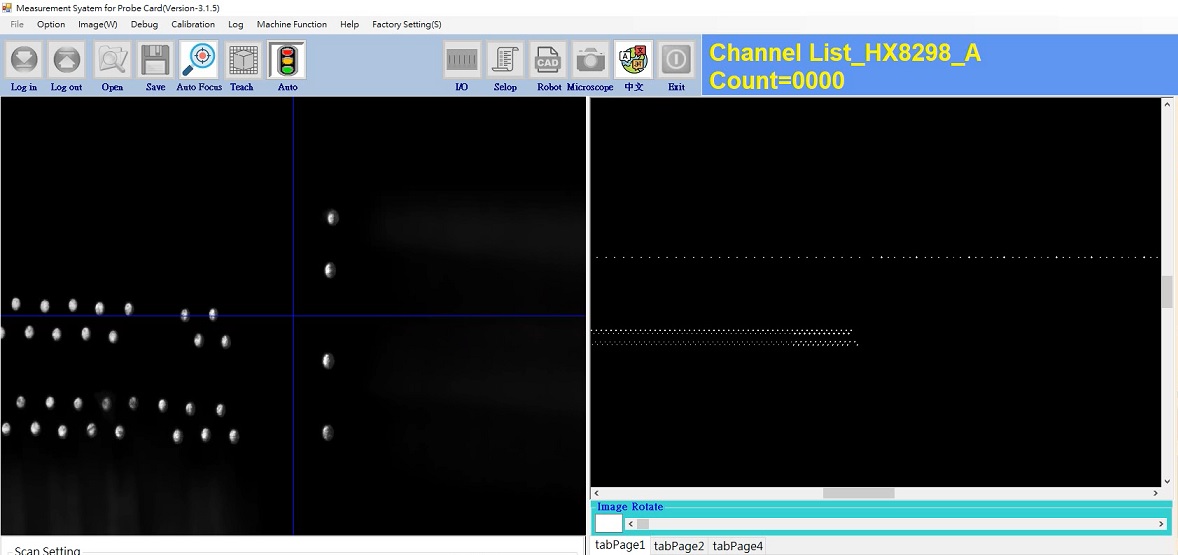

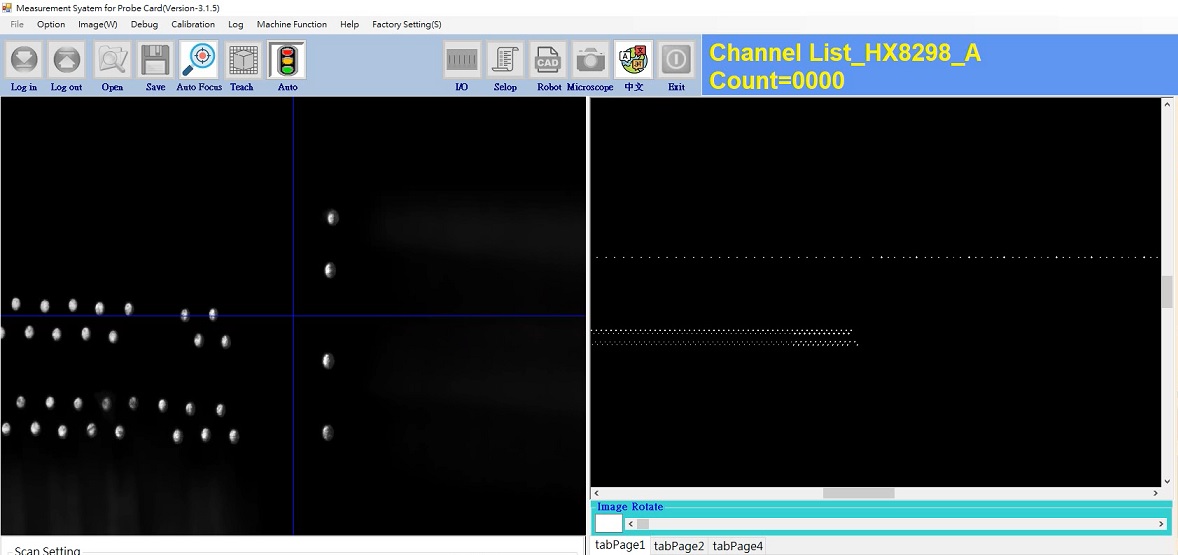

Superior software algorithm can accurately correct the shift during mapping and quickly complete the seam map

Import the location EXCEL file to accurately calculate the needle position, needle diameter and needle level

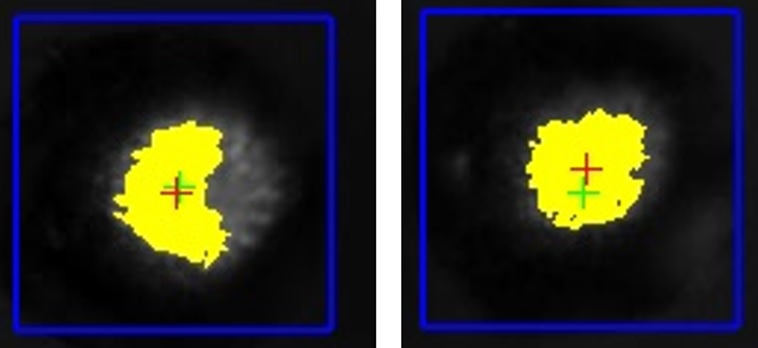

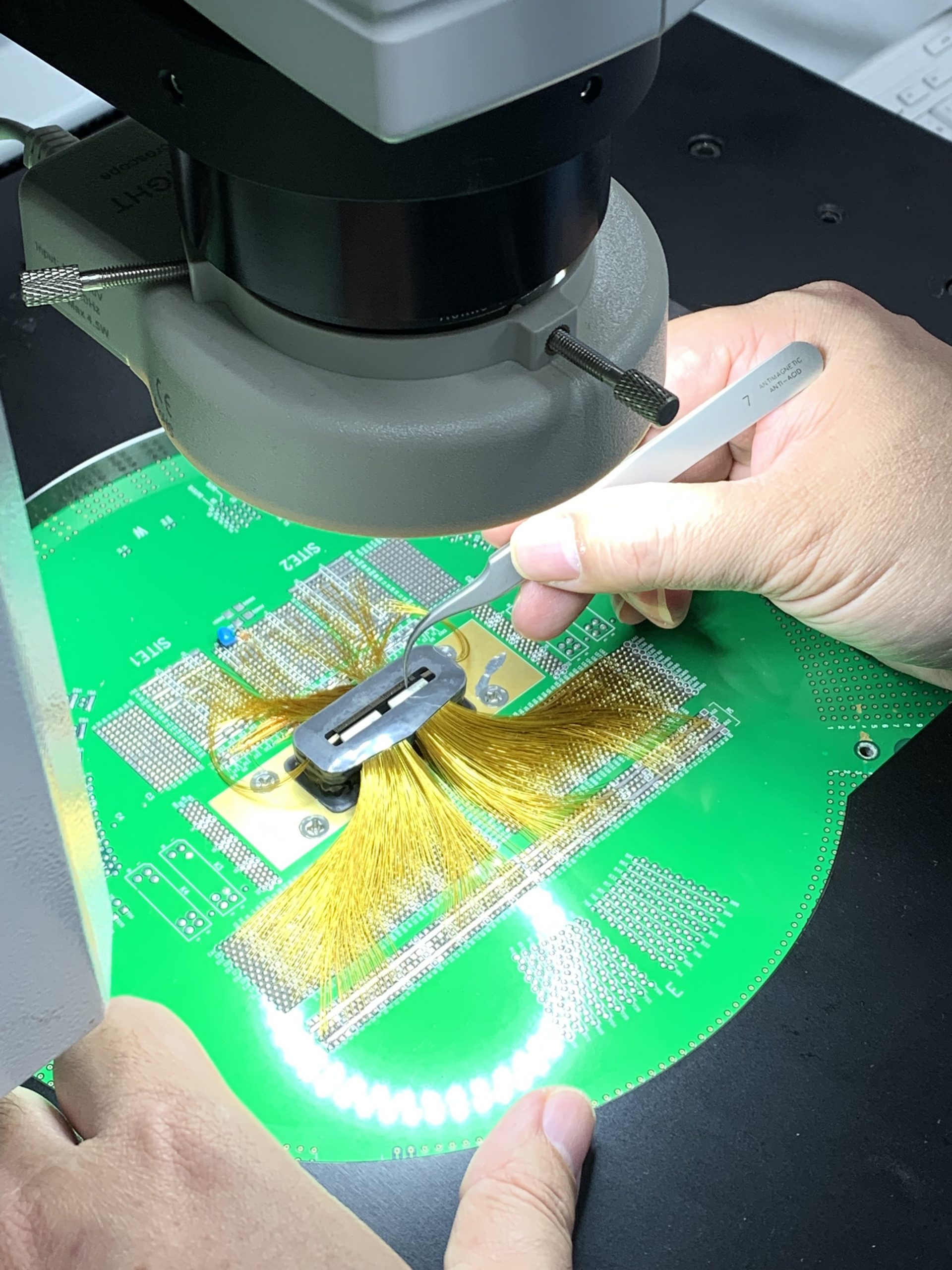

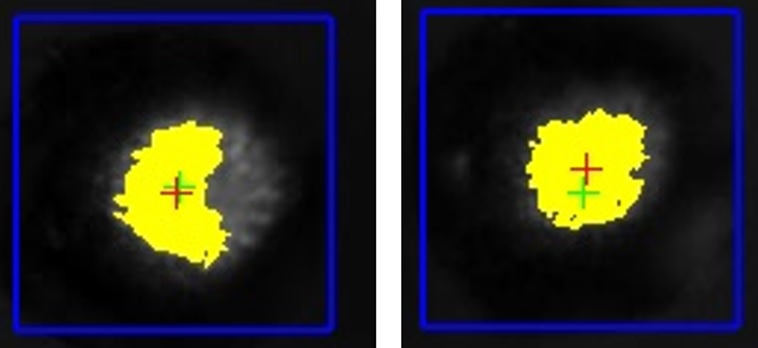

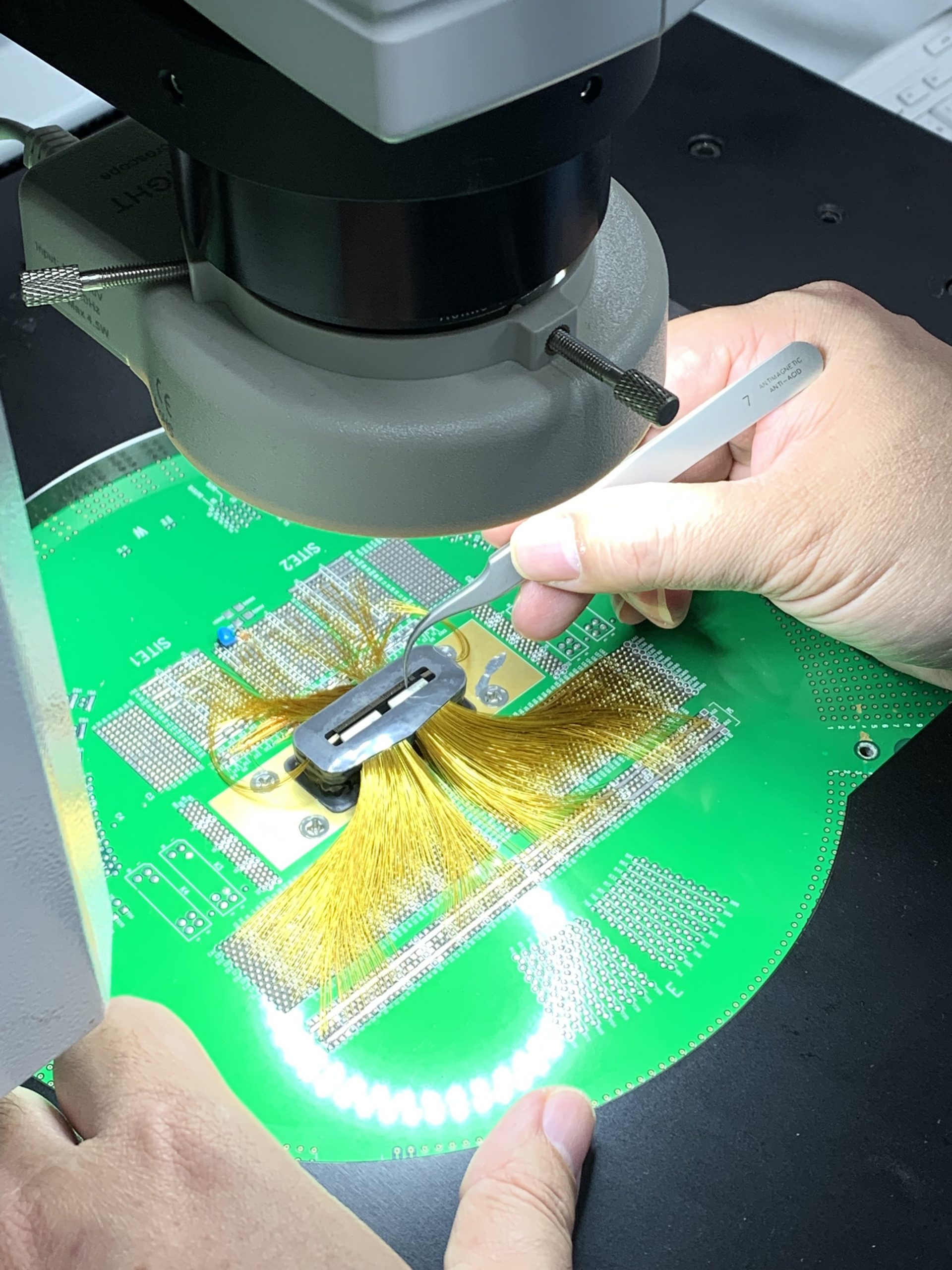

Through the calculation and analysis of the software, the offset between the standard needle position and the actual needle position can be measured, and the needle can be adjusted

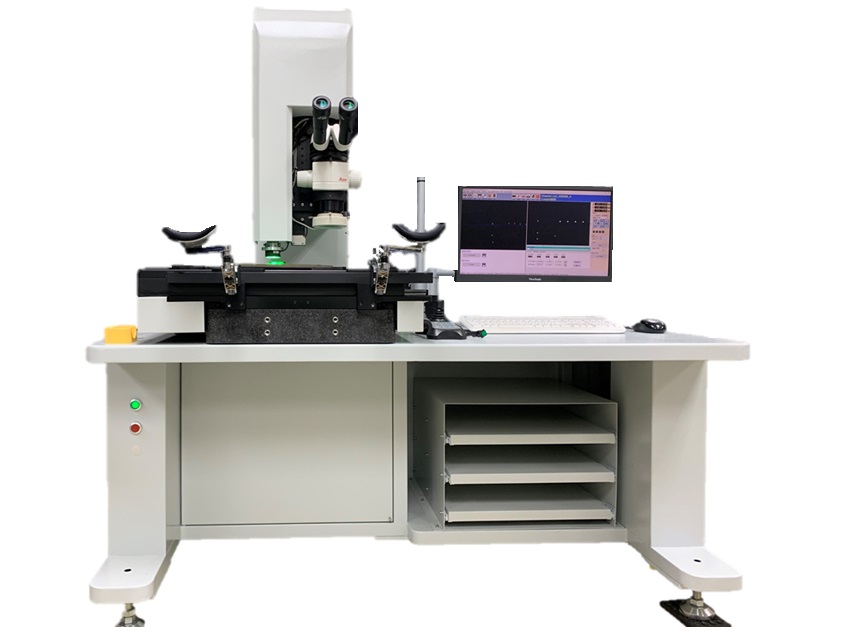

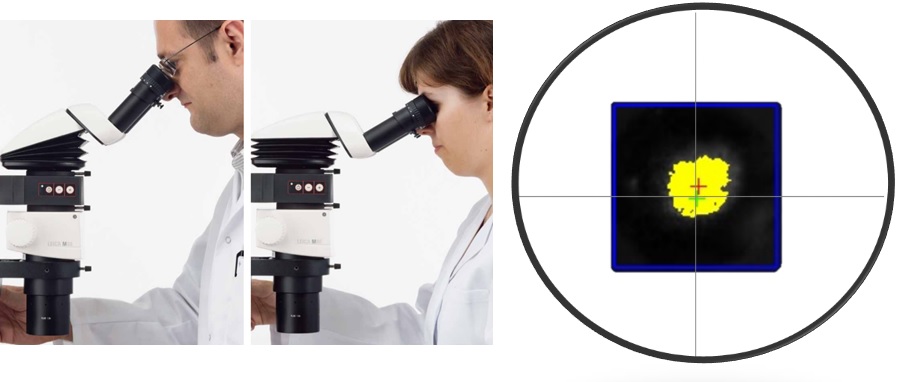

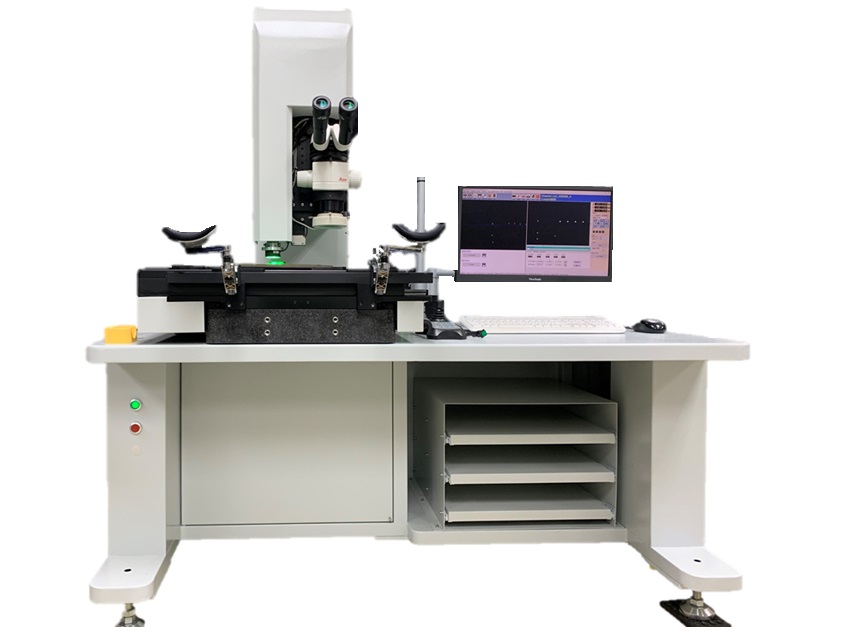

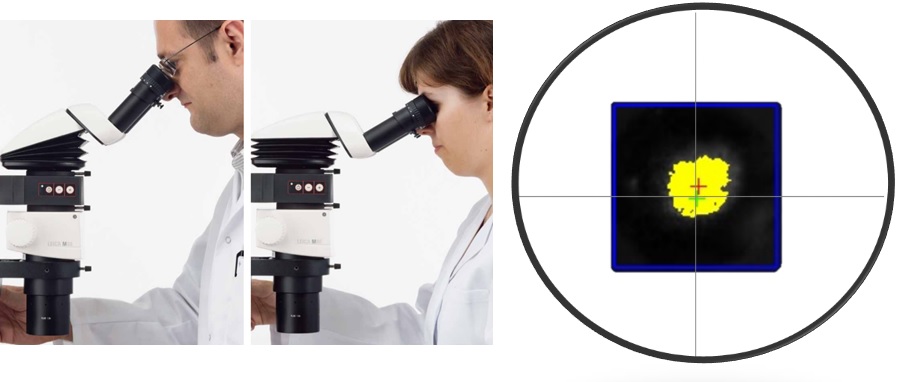

Adopt LEICA optical microscope made in Germany, equipped with 25 times eyepiece, the total optical magnification is 18-125 times

The eyepiece is built with a special ultra-fine reticle (3um) to facilitate alignment

The TITING three-eye observation head is adopted, and the height of the observation lens barrel can be adjusted according to the height of the operator

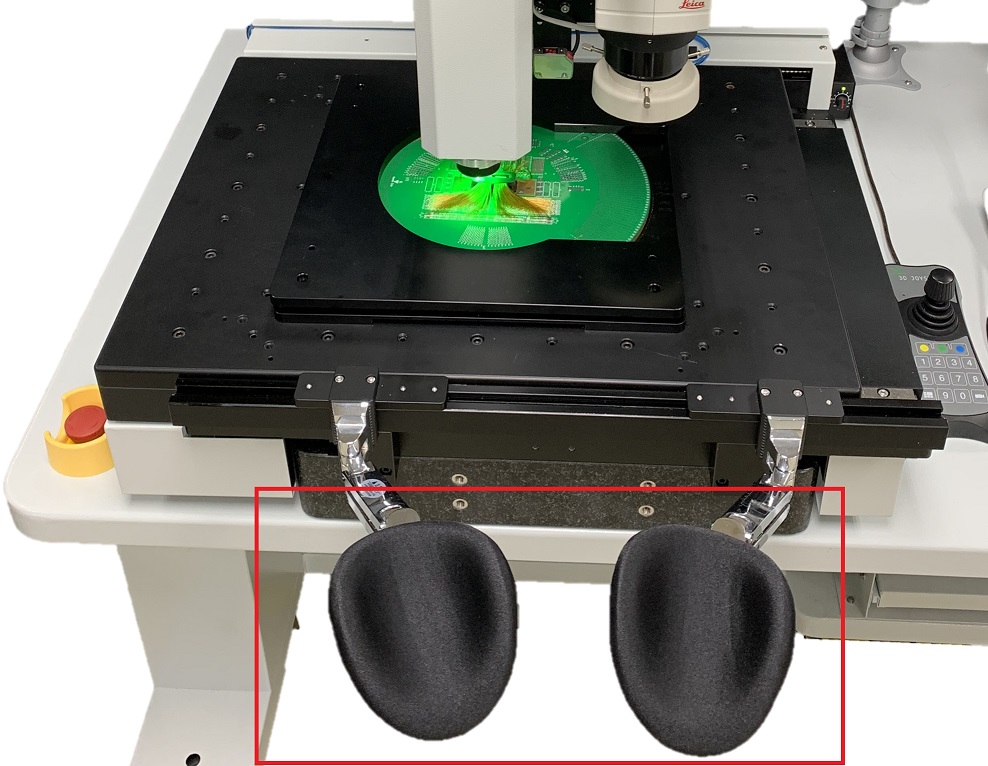

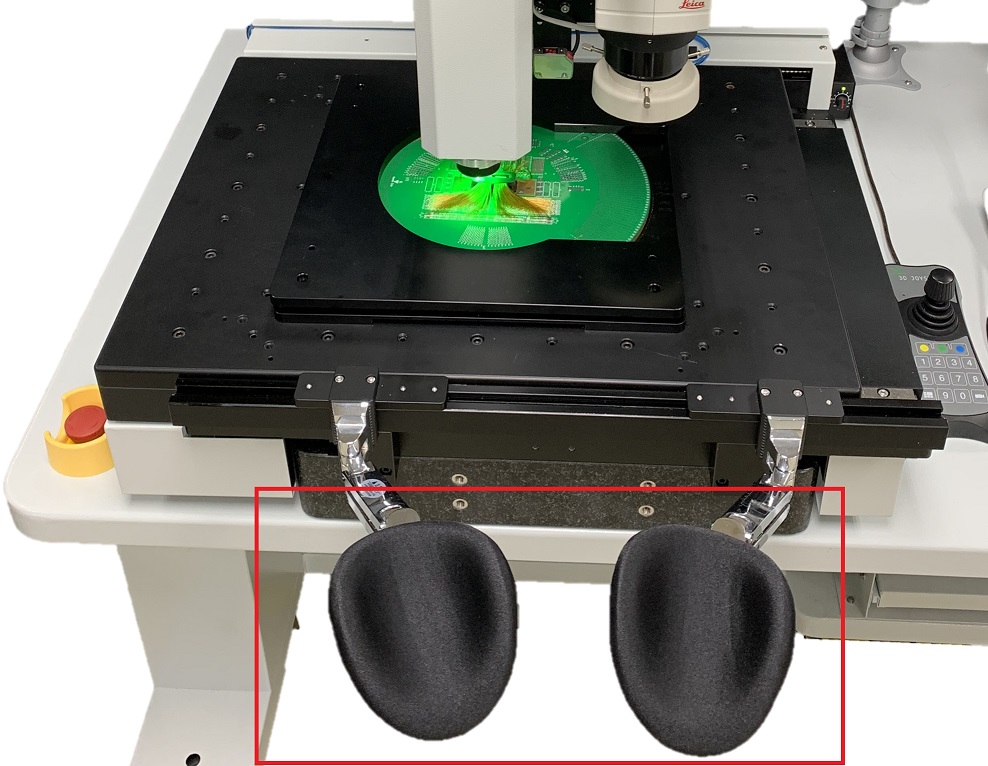

Ergonomic design can greatly reduce the fatigue of personnel adjusting needles and repairing cards for a long time

Needle adjustment machine detection system—

excellent measurement results

●The equipment machine adopts 0.1um optical scale, high repeatability, and the best measurement repeatability in the industry

●Detected needle diameter > 8um, needle position deviation > 3um

●With an anti-collision mechanism, the risk of card collision can be avoided during operation

●Intelligent needle adjustment operation, the fastest needle adjustment assistance in the industry, the speed can be better than PRVX, saving more than 50% compared with traditional needle adjustment time

●Automatic software compensation and correction, which can quickly correct the coordinates of the machine to achieve more accurate measurement

●Ergonomically designed machine, reducing the fatigue of personnel operating for a long time

●Specially made ten-card-in-one jig, probe cards of various sizes can be accurately aligned horizontally