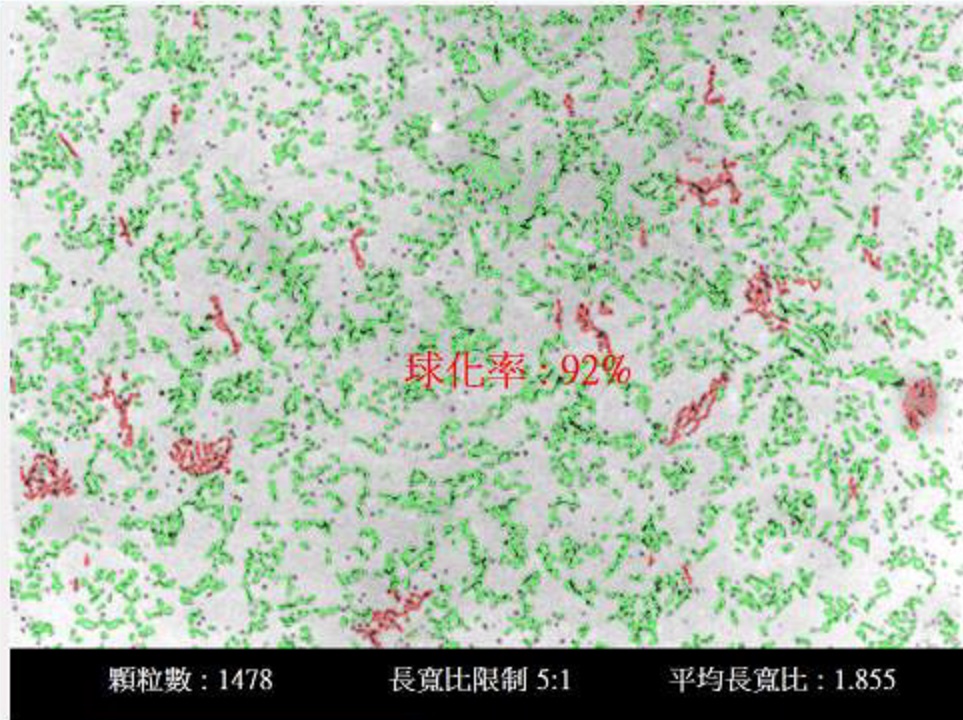

Analysis of vermiform spheroidization rate of cast iron

Through heat treatment, the long strips of carbide in the iron are turned into granular carbides. The metallographic diagram is taken with a microscope (500 times) and the carbide particles are calculated to meet the length and width [...]

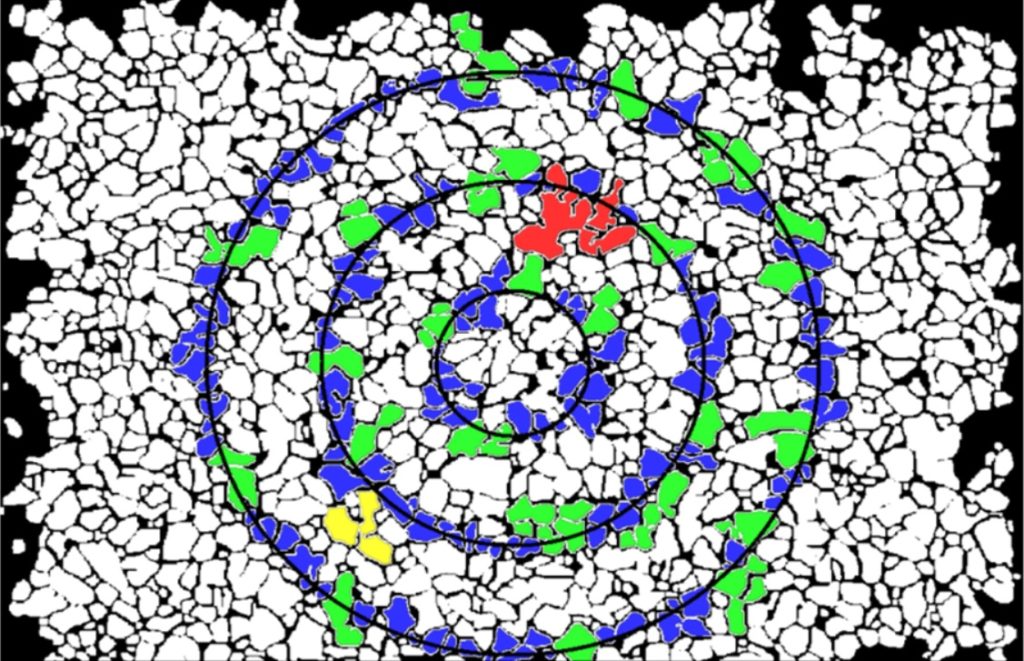

GRAIN SIZE Grain size analysis

In the special alloy part, the analysis of the grain size and gray-scale metallography in the metallography. The number of grain size levels will have its impact on the product and processing process. The finer the grains, […]

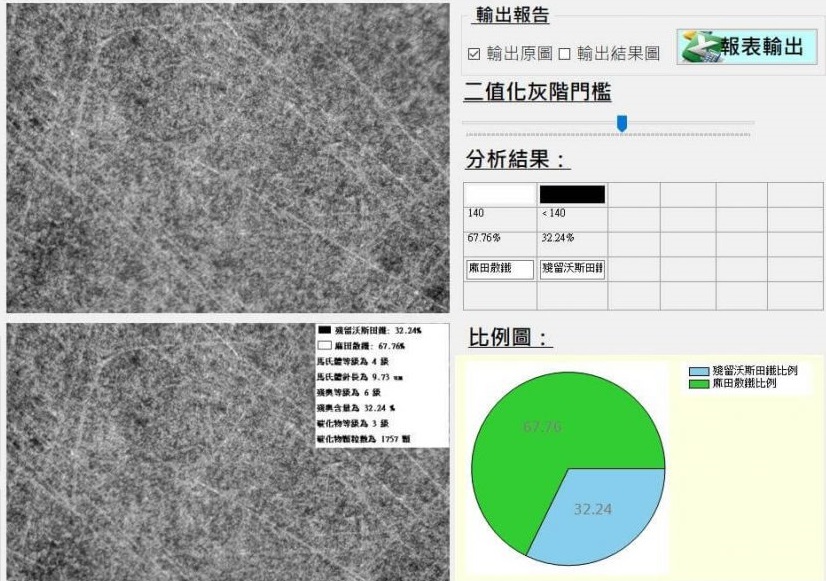

Automated decarbonization depth calculation and analysis

The FOC-R decarburization layer is defined as the distance from the initial position of decarburization to the surface. It can be divided into fat iron decarburization layer, partial decarburization, and full decarburization (fat iron + partial decarburization) […]

Metallographic Analysis of Steel Carburizing and Quenching

The metallographic analysis is needle-shaped and spherical iron (steel quenching) and tempered metallographic analysis of carburizing and quenching of steel parts, in line with China’s national standard GB/T […]

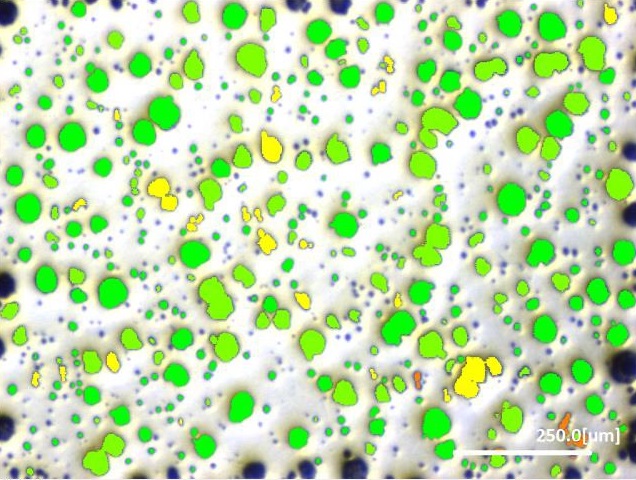

Analysis of cast iron graphite nodularization rate

The detection method of ductile iron spheroidization rate is calculated by true roundness in accordance with American standards ASTM A247, E2567-13, based on the width of the graphite particles […]

Analysis of metal intervening objects (inclusions)

In the steelmaking industry, the commonly used metallographic analysis is the analysis and discrimination level of inclusions (inclusions). Five levels are defined as the level classification of inclusions. If you have relevant […]

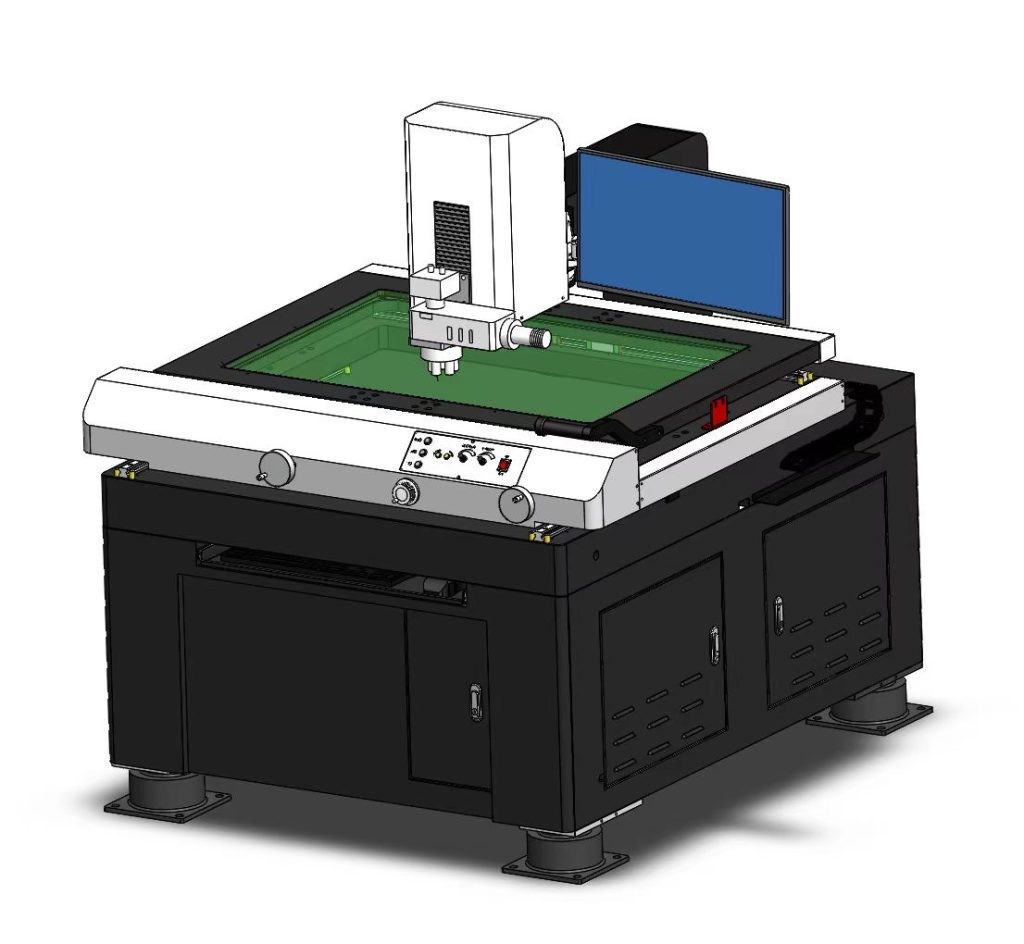

AOI image stitching analysis and measurement system

Image processing for various products uses high-speed computing algorithms to process the size measurement and defect determination of the object under test. It is used in the semiconductor industry, optoelectronics, biomedicine and industrial [...]