To meet the needs of full inspection and rapid manufacturing production

We provide clients with flexible customization needs

Provide solutions to software detection and measurement needs using existing equipment modules

Solution example:

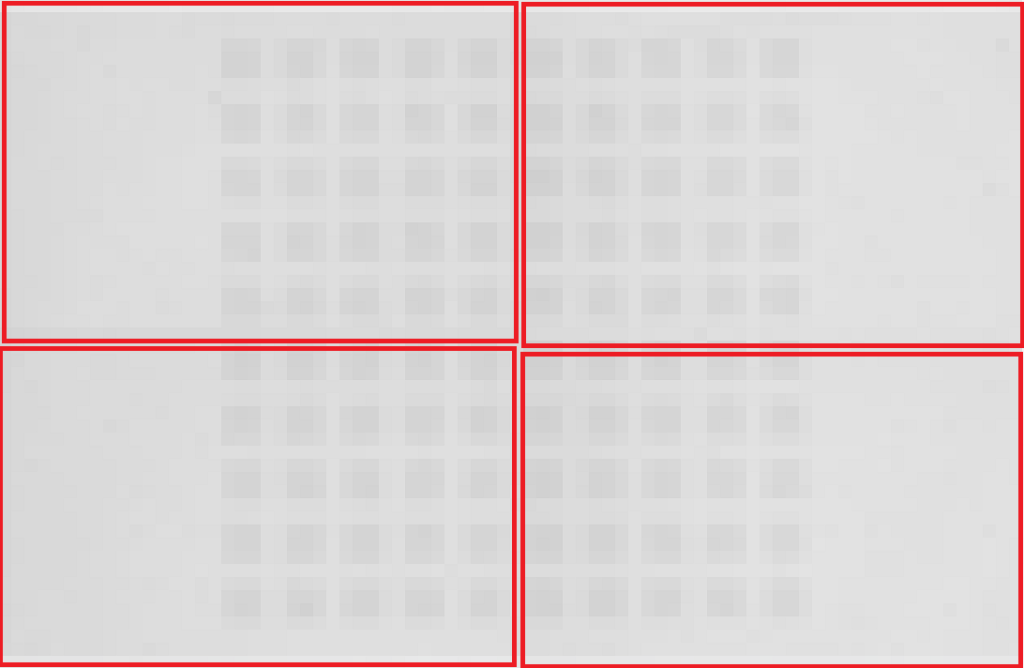

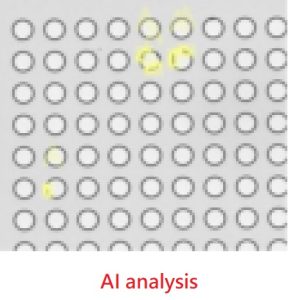

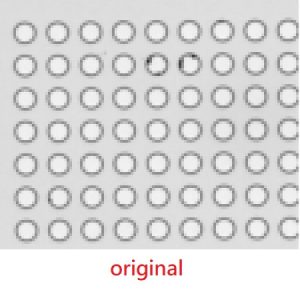

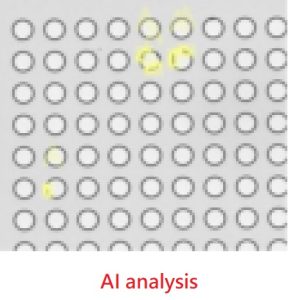

Image stitching using an automatic stage and a wide-field optical lens with a 20-megapixel camera

Take a photo from each of the four quadrants and stitch it into a complete finished picture.

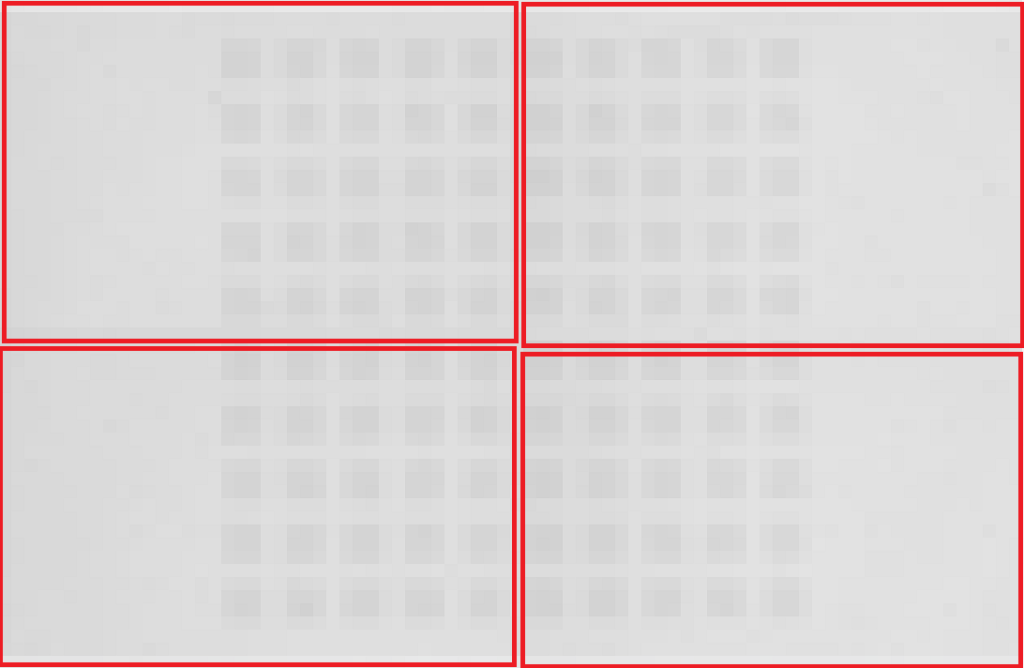

Divide the entire image into 20X20 images

Quickly analyze defects and measure measurements

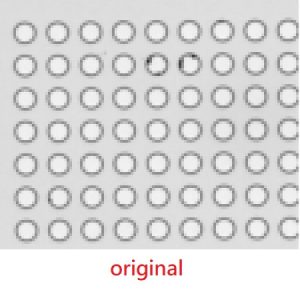

AI software can be used to accurately determine the PASS or NG of a product after deep learning.

Provide a variety of hardware mechanisms and loading and unloading methods:

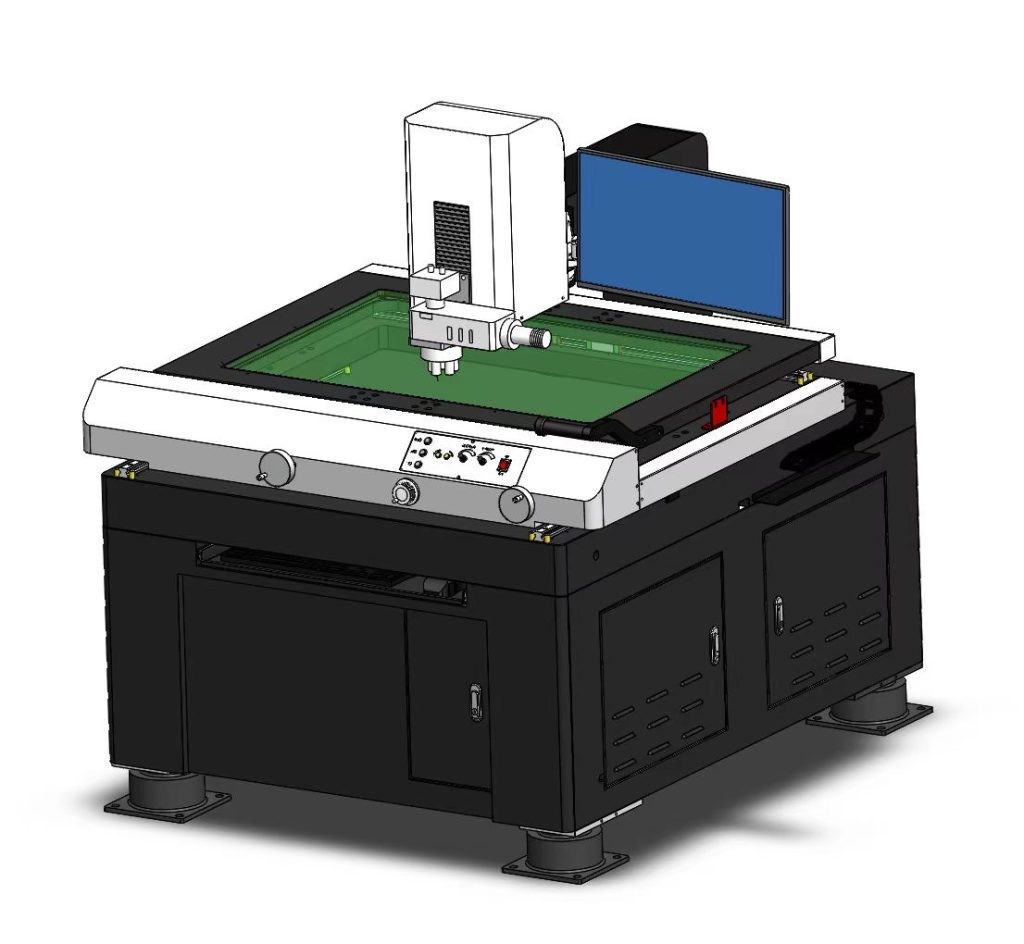

Customized mechanism, large-stroke mobile stage, suitable for large-sized workpieces

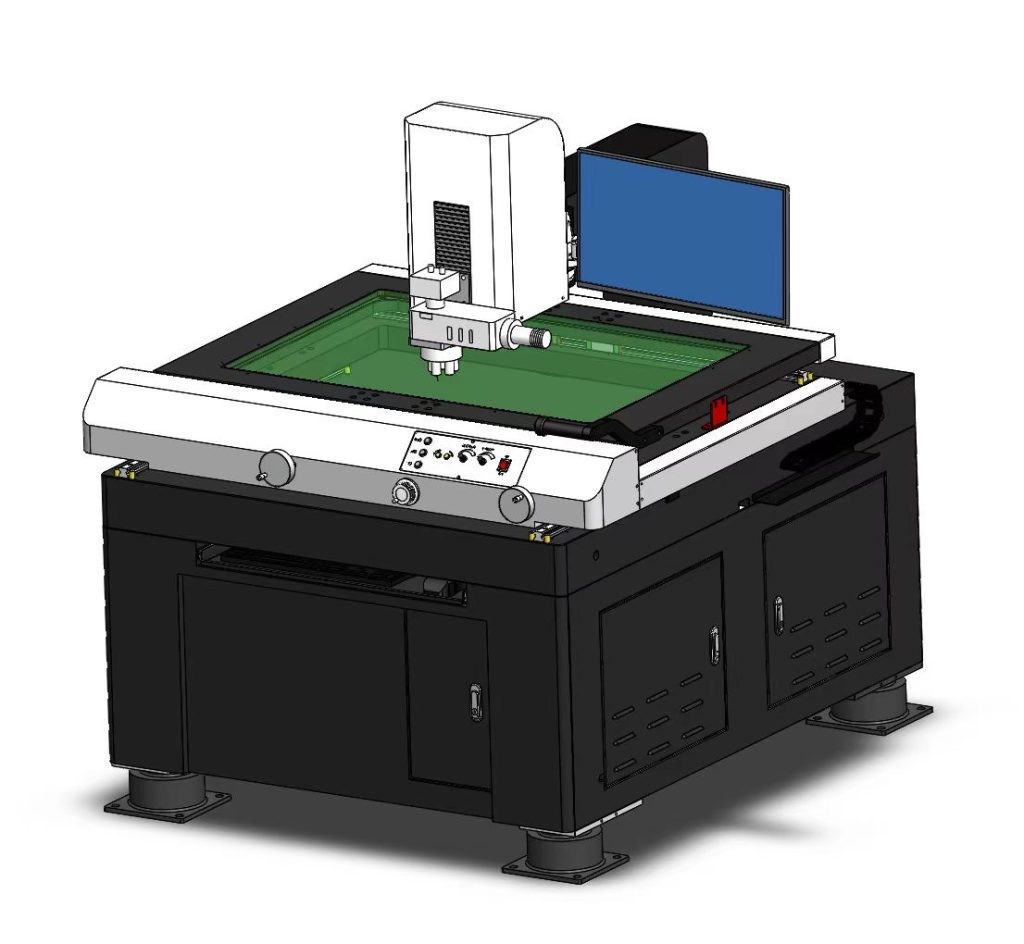

Floor-standing mechanical equipment, equipped with a large field of view lens and a 12-inch XY automatic stage

For more solutions, please call us.

1. AI defect learning and determination software

2. Equipped with electric stage for MAPPING function

3. XYZ optical ruler, accurate positioning

4. Geometric element measurement and form and position tolerance measurement

5. CAD drawing files can be imported to combine workpiece drawings

6. Report data export and report customization

7. Establishment of measurement and analysis judgment templates

8. Can be connected to a barcode machine to access files

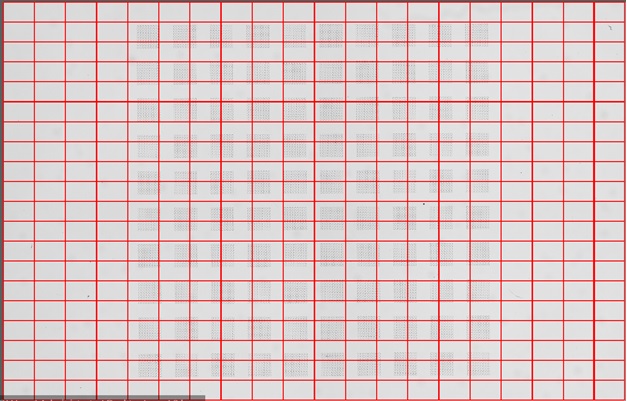

Specification example of floor-standing mechanism

| working distance(mm) |

145± 2mm |

| XYMoving stroke |

350*250 |

| Workpiece load weight |

20KG |

| Workbench lifting stroke |

150mm |

| Focus on Z axis |

auto focus |

| Drive control |

Independent motor control |

| Optics

system |

Lens magnification |

0.64X/0.16X |

| FOV (field of view) |

80*50/20*14 mm |

| Repeat accuracy |

±5µm |

| Movement accuracy |

3+(L/200)um |

| camera |

20 million pixel industrial camera |

| Light source system |

surface light, contour light |

| size |

1000*690*1755mm |

| weight |

About 500KG |

| software |

Professional version analysis and measurement software |