Needle-shaped hemp field loose ironIt is often used for quenching or induction hardening of steel parts.

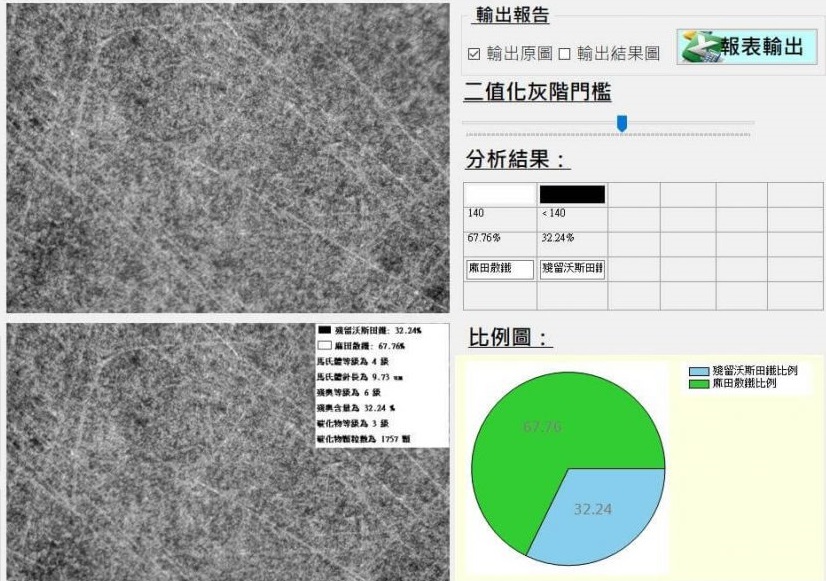

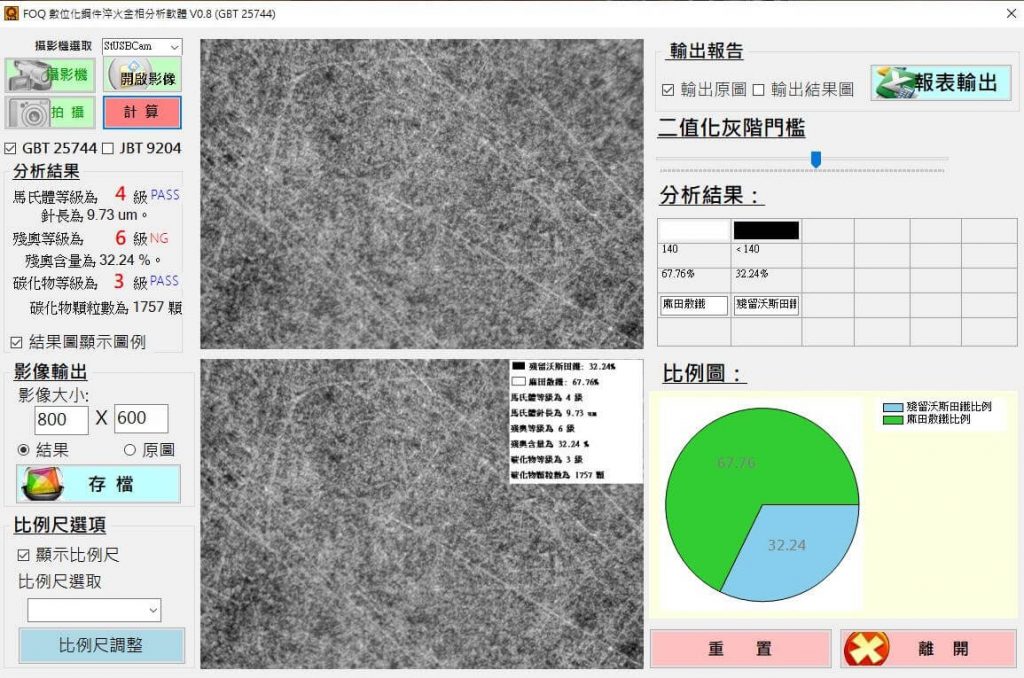

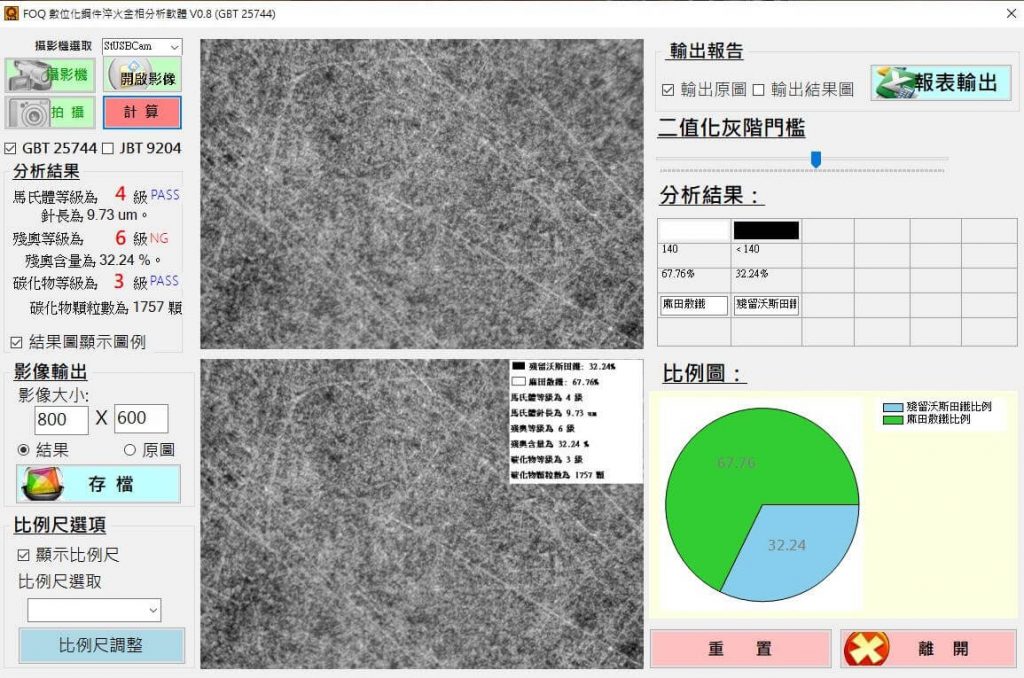

Steel quenching metallographic analysis software (FOQ)Artificial intelligence is used to increase the accuracy of determination of the needle length and rating of needle-shaped Asada loose iron, the residual Waston iron content and rating, the number and rating of carbide particles, etc., and is based on the principle of easy use and output. , reduce the burden on inspection personnel, improve the yield rate of steel parts quenching processing, also enhance the company's industrial competitiveness, and ensure quality and product delivery.

- Real-time identification of steel quenching conditions;

- Record the identification results of steel quenching or induction heating quenching with one click;

- Output digital reports with one click;

- All identification results can be recorded digitally.

- The benefits of steel quenching metallographic analysis software on subsequent processing:

a. Ensure the quenching effect so that the workpiece meets the ratio of needle length and residual Waston iron required by the customer after quenching.

b. The hardness value of the steel can be maintained stable, and the hardness value distribution will not be different due to structural differences.

c. Adjust the mechanical properties of steel to meet usage requirements.

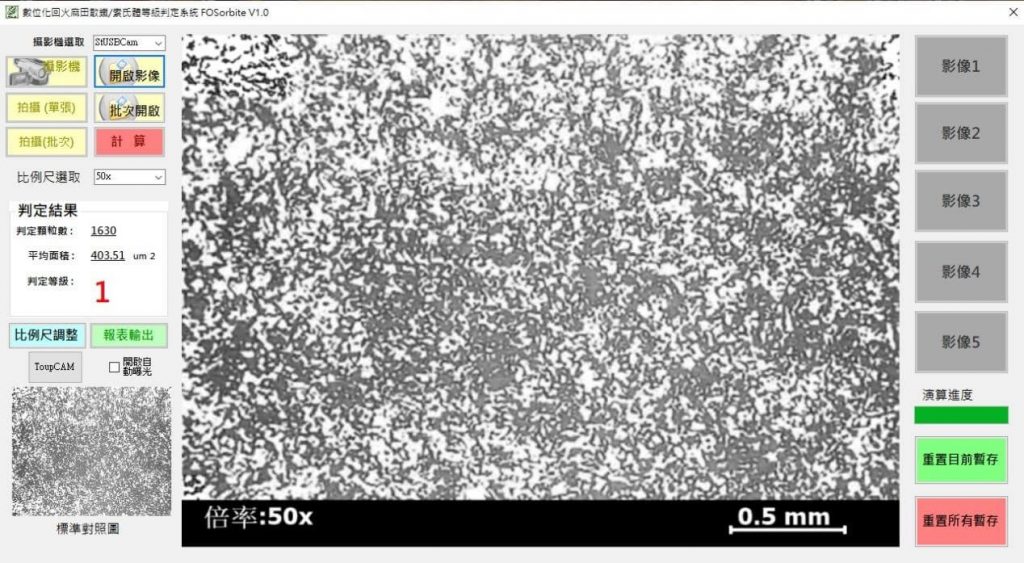

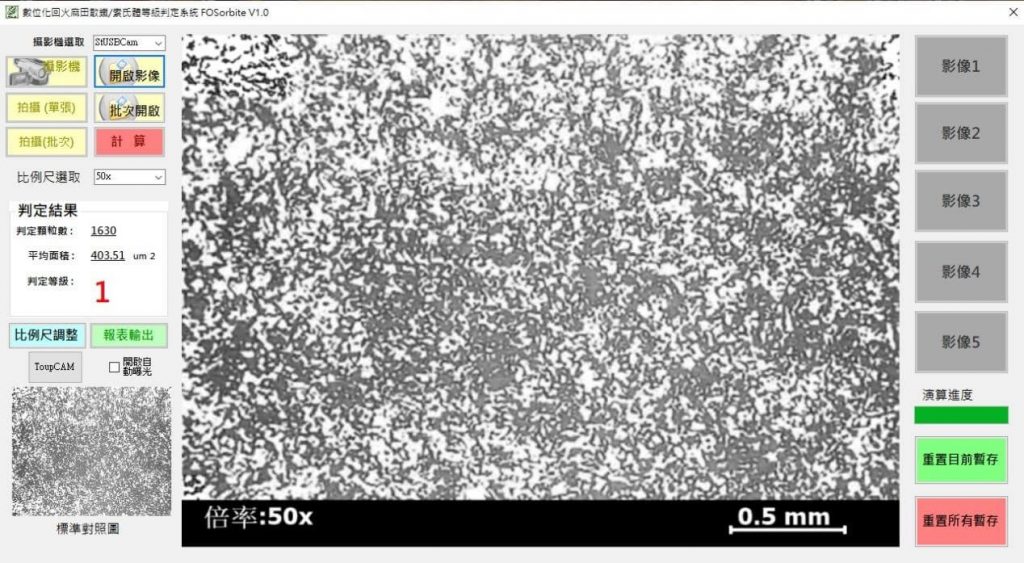

Tempered Asada bulk iron and sorbite detection software (FOSorbite)It mainly detects the metallographic phase of steel that is tempered after quenching, and evaluates whether there is tempered iron and sorbite.

This software removes human and subjective judgment methods, refers to the Chinese GBT-13320 specification, and uses the intelligent function of the software to objectively and accurately automatically determine the status of tempered iron and troxite.

- The benefits of tempered Asada bulk iron and sorbite detection software on subsequent processing:

a. Improve the structural stability so that the workpiece will no longer undergo structural transformation during use, thereby maintaining stable geometric dimensions and performance of the workpiece.

b. Eliminate internal stress to improve the performance of the workpiece and stabilize the geometric dimensions of the workpiece.

c. Adjust the mechanical properties of steel to meet usage requirements.

Sales Representative Customer -Yadeke, Liuyao Industry

[Features of MDS-PRO metallographic analysis software]

●All-round solutions

Provide integrated solution services, which can be combined with our own equipment at the same time, such as metallographic pre-processing equipment, image capture equipment, etc., and conduct product education and training to seamlessly connect inspection personnel with this product

●Easy to use

Easy to use, no more cumbersome settings

●Intelligent judgment

Artificial Intelligence, Improving Identification Accuracy

●Digital test results

Recognition result images and data can be output with one click, providing reliable and useful information.

[Sales Performance] (The list is being added...)

Sinosteel Malaysia, Qingda Technology, Yingming Industrial, Changjing Industrial, Jinchun Industrial, Chiayi Steel, TOEFL Industrial, Dacheng Stainless Steel, Taiwan Fastener Industry Technology Development Association, Fengjia University, China Steel, Yaoshen Industrial, Metal Center , Haihua Steel, Xinyongcheng Steel, Zhennan Railway Line, Hengmao Hardware, Chaofeng Industrial, Global Inspection Technology, Jianfa Advanced Technology, Shencheng Industrial, Shuren Medical College, Taipei University of Science and Technology, Mingming Aluminum, Fidelity Aerospace, International Linear, Qingxinxin Steel, Jianxin Technology, Huwei University of Science and Technology, Xintai Steel, Mengying Technology, Chenwei Metal Industry, Tomita Electric, Standard Inspection Technology, Non-Ferrous Industry, Airtac

- Software specifications and reference specifications:

FOQ steel quenching metallographic analysis software:

- Determine according to GB measurement standards

- Automatic measurement and analysis of martensite, paralytic and carbide grades

- Automatic measurement and analysis of martensite needle length, Parasite inclusion, Parasite content, and carbide inclusion particle number

- Automatically calculate the grain grade and average size of high-frequency metallographic structures of steel parts

- Directly capture images for quenching metallographic analysis

- Output BMP, JPG, Excel reports

- It has a high-level copy protection program to prevent the leakage of your company’s important assets.

- Photos taken previously can be opened for calculation

- Can be combined with CCD or read historical images for interpretation

- Customized report output

- Image results can be output as original images or detection result images.

[Refer to international standards and specifications]

GBT 25744

JBT 9204

FOsorbite backfired bulk iron detection software:

- Refer to GB measurement specifications for judgment.

- Automatically measure the average area and particle number of tempered Asada loose iron and sorbite in the metallographic structure.

- It can be compared with the standard comparison chart to compare the tempered Ma Tian bulk iron and troostite grades.

- Directly capture the image for analysis of tempered iron and sorbite.

- Directly analyze images from five fields of view and present them directly in the report.

- Output BMP, JPG, Excel® reports.

- It has a high-level anti-copy protection program to prevent the leakage of your company's important assets.

- You can open previously taken photos for calculation.

- It can be combined with CCD or read historical images for interpretation.

- Customized report output.

- The image results can be output as original images or detection result images.

[Refer to international standards and specifications]

GBT 13320-2007