Ductile iron nodularity detection software (FOD)Use artificial intelligence to improve the accuracy of determining the nodularity rate of ductile iron; and based on the principles of simple use and simple output, reduce the burden on inspection personnel, so that your company can ensure high product yield, improve company quality and industrial competitiveness, and ensure quality and product delivery.

- Instantly identify the spheroidization rate of ductile iron;

- Record the digital spheroidization rate identification results with one click;

- One-click output of digital spheroidization rate report;

- All identification results can be recorded digitally.

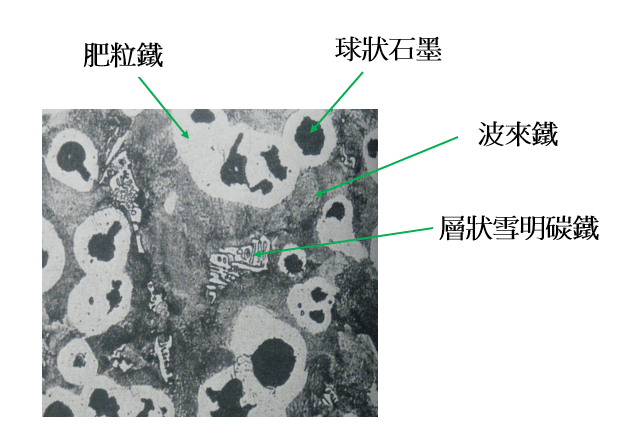

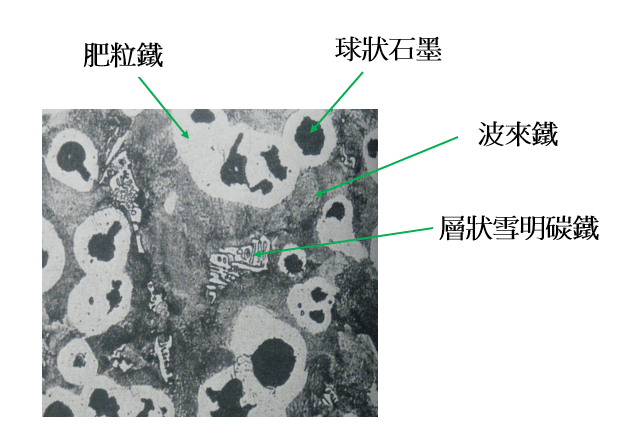

*Nodular cast iron: Gray cast iron is a high-performance cast iron that precipitates into spherical graphite after spheroidizing treatment.

- The benefits of spheroidization rate software for subsequent processing

- Reduce wire hardness and deformation resistance.

- Increase wire ductility and cold forging material formability.

- Stable spheroidization rate,Product yield is improved.

- Avoid brittle fracture of screws.

- Reduced failure rate,Production costs are reduced.

- Reduced wear on the drawing die,Production efficiency is improved.

- It can effectively enable buyers and sellers to decide on acceptance criteria.

The influence of ductile iron spheroidization rate on products and processing

a. After cast iron is spheroidized, its structural strength can be increased to reduce the occurrence of brittle cracks.

b. Spheroidizing treatment can form a composite structure between the graphite in the cast iron and the fat iron base.

c. The higher the spheroidization rate of cast iron, the higher the shock absorption (damping coefficient) and impact resistance strength.

[Features of MDS-PRO metallographic analysis software]

●All-round solutions

Provide integrated solution services, which can be combined with our own equipment at the same time, such as metallographic pre-processing equipment, image capture equipment, etc., and conduct product education and training to seamlessly connect inspection personnel with this product

●Easy to use

Easy to use, no more cumbersome settings

●Intelligent judgment

Artificial Intelligence, Improving Identification Accuracy

●Digital test results

Recognition result images and data can be output with one click, providing reliable and useful information.

[Sales Performance] (The list is being added...)

Sinosteel Malaysia, Qingda Technology, Yingming Industrial, Changjing Industrial, Jinchun Industrial, Chiayi Steel, TOEFL Industrial, Dacheng Stainless Steel, Taiwan Fastener Industry Technology Development Association, Fengjia University, China Steel, Yaoshen Industrial, Metal Center , Haihua Steel, Xinyongcheng Steel, Zhennan Railway Line, Hengmao Hardware, Chaofeng Industrial, Global Inspection Technology, Jianfa Advanced Technology, Shencheng Industrial, Shuren Medical College, Taipei University of Science and Technology, Mingming Aluminum, Fidelity Aerospace, International Linear, Qingxinxin Steel, Jianxin Technology, Huwei University of Science and Technology, Xintai Steel, Mengying Technology, Chenwei Metal Industry, Tomita Electric, Standard Inspection Technology, Non-Ferrous Industry, Airtac

- Software specifications and reference specifications:

FOD ductile iron spheroidization rate detection software:

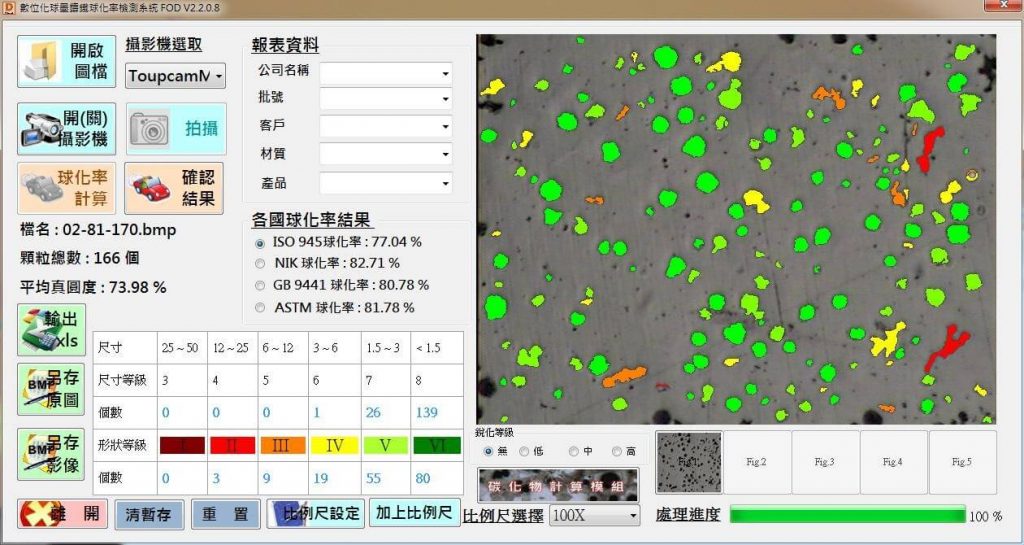

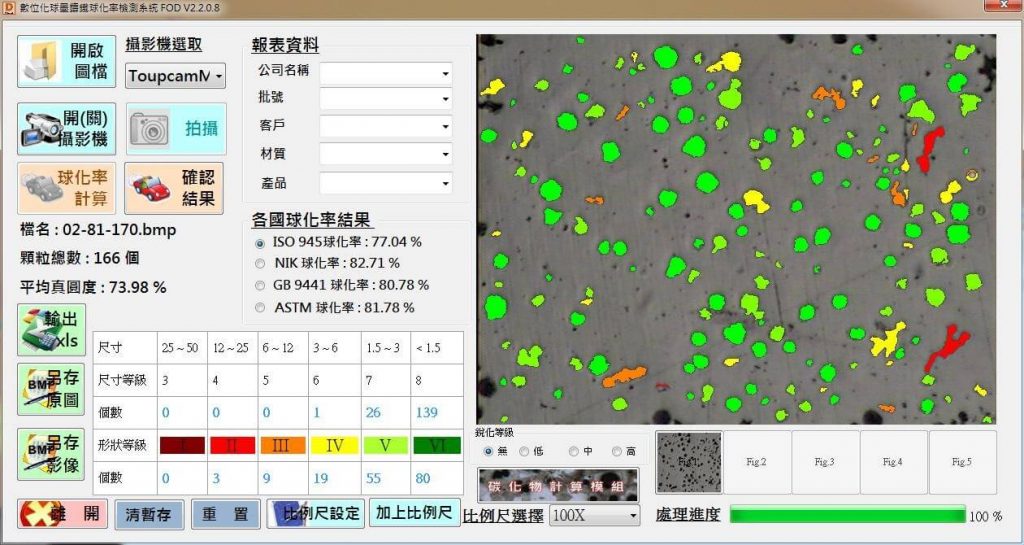

- Determine with reference to JIS, ASTM, GB, ISO and other measurement standards.

- Can automatically measure the nodularity rate of ductile iron with metallographic structure

- Can calculate the proportion of fat iron, snow carbon iron and ductile graphite

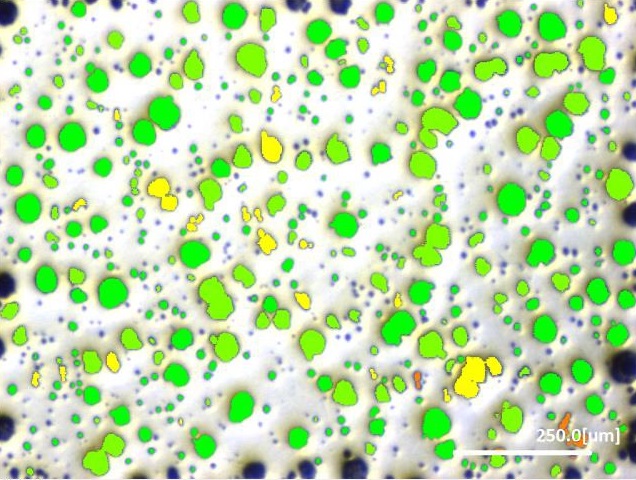

- Automatically mark the distribution of ductile iron nodularity rate with color

- Directly intercept images to analyze the nodularity rate of ductile iron

- Directly analyze images from five fields of view and present them directly in the report

- Export BMP, JPG, Excel® reports

- It has a high-level copy protection program to prevent the leakage of your company’s important assets.

- Photos taken previously can be opened for calculation

- Can be combined with CCD or read historical images for interpretation

- Customized report output

- Image results can be output as original images or detection result images.

[Refer to international standards and specifications]

JIS G5502:2001

ISO 1083

ASTM A247

ASTM A536-84(2009)

ASTM E2567-13

GB/T 9441-2009