100% Made in TaiwanNovel appearance design, comparable to imported grade equipment

After years of market feedback and improvements, it has been widely used in

Various materials processing industries.

100% Made in TaiwanNovel appearance design, comparable to imported grade equipment

After years of market feedback and improvements, it has been widely used in

Various materials processing industries.

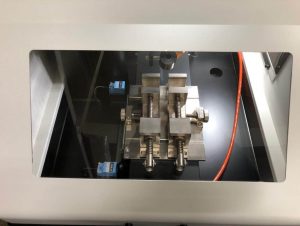

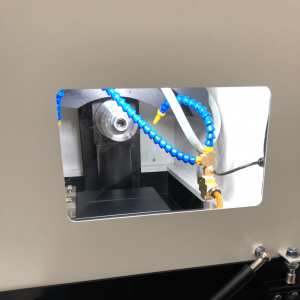

The bright and refreshing cutting room allows for clear observation of the cutting process

There is a cleaning water source inside, so the room can be flushed after use.

To maintain the life of the machine and the cleanliness of the environment

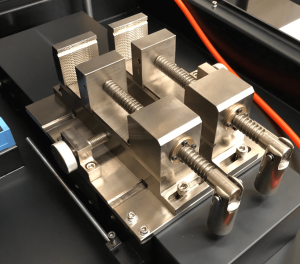

Professionally designed clamps to stabilize vibrations generated during cutting

This allows the material to be cut flat.

The clamps can be used to clamp various materials.

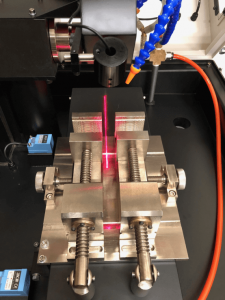

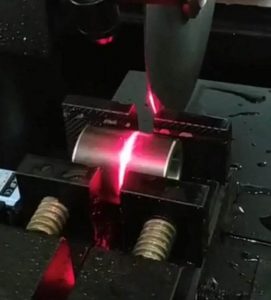

Laser tool setting light source

Can clearly know the cutting position and fine-tune the position before cutting

The conditions in the cutting chamber can also be observed from the side

Observe the cutting process from multiple angles

Load display:

If the load is found to be too high or too low during the cutting process

You can adjust the feed speed or remind you that the cutting blade needs to be replaced.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||