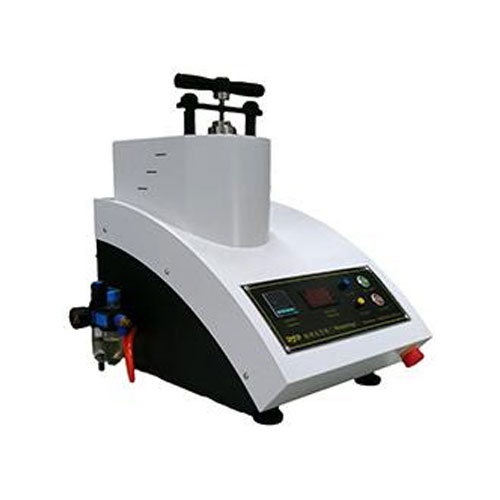

The first pneumatic pressurizing system in Taiwan, the pressure is stable and can be adjusted freely.

Compared with traditional hydraulic mechanisms, there is no oil leakage problem and no oil pollution in the environment.

The first pneumatic pressurizing system in Taiwan, the pressure is stable and can be adjusted freely.

Compared with traditional hydraulic mechanisms, there is no oil leakage problem and no oil pollution in the environment.

The first pneumatic pressurizing system in Taiwan, the pressure is stable and can be adjusted freely.

Compared with traditional hydraulic mechanisms, there is no oil leakage problem and no oil pollution in the environment.

The operation panel is simplified and the efficiency is doubled.

The bridge-type upper cover design makes locking/unlocking effortless.

The cooling temperature is adjustable so that the embedded mold does not burn your hands or get burned by metal parts.

The mirror-type operation panel is beautiful and elegant.

An external water pump can also achieve automatic cooling effect.

One-touch button operation to achieve perfect efficiency of automatic heating, automatic pressurization and automatic cooling

Labor-saving design, place the handle into the tenon and lock it

Just press start and wait for it to take shape.

You can handle other matters first while waiting.

Forming time is about 8 minutes (can be set by yourself)

Save time and effort.

Pneumatic design can avoid traditional hydraulic design

Oil leakage problem due to age.

There is a water vapor filtering device inside the machine, so there is no need to worry about the water vapor problem generated by the air compressor.

Various colors of embedded powder, even transparent embedded powder

Anyone can use this machine, after many customer test feedback

The quality was well received.

| Product specifications: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||