Applications

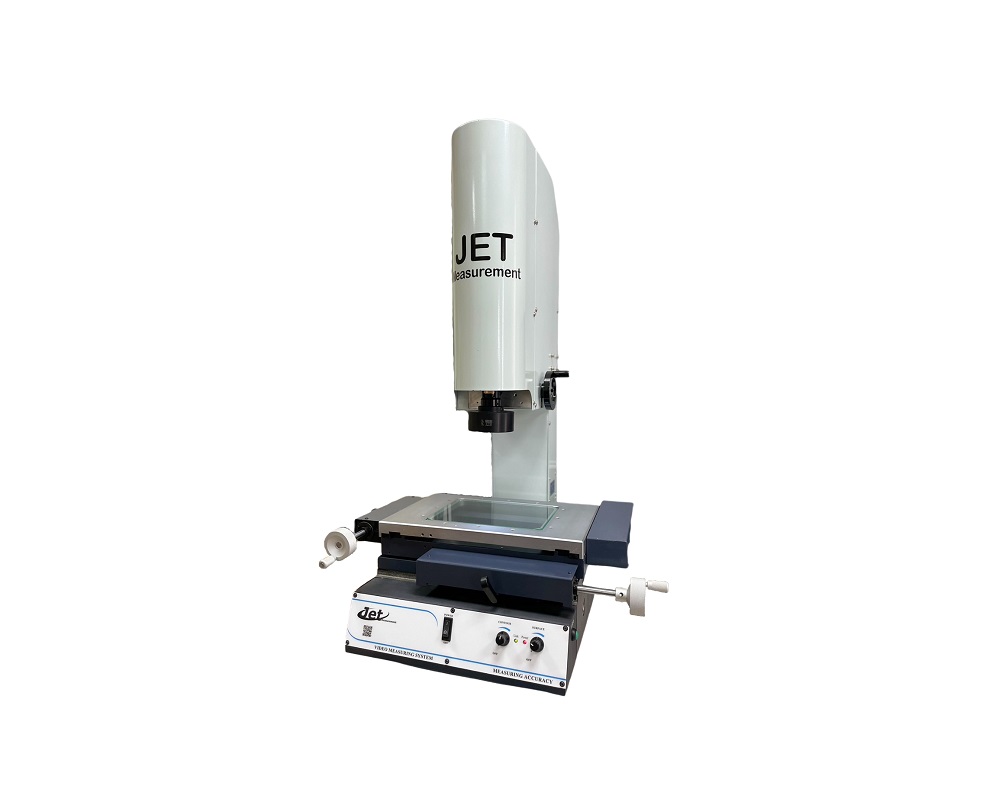

It can detect the contours, surface dimensions, angles and positions of various precision parts. It can also perform microscopic observation, inspection and quality control of products, and can be used for product development and other functions.

Suitable for various industrial applications

Special applications:

The measurement method is mainly two-dimensional measurement, using geometric elements such as points, lines, arcs, and rectangles to measure the length, length, and length of the workpiece.

Measurement of angles, contours, surface shapes and other requirements, with the device of auxiliary accessories, height can also be measured at the same time

Measurements, such as the height of steps, the depth of holes or grooves, etc.

Machine equipment:

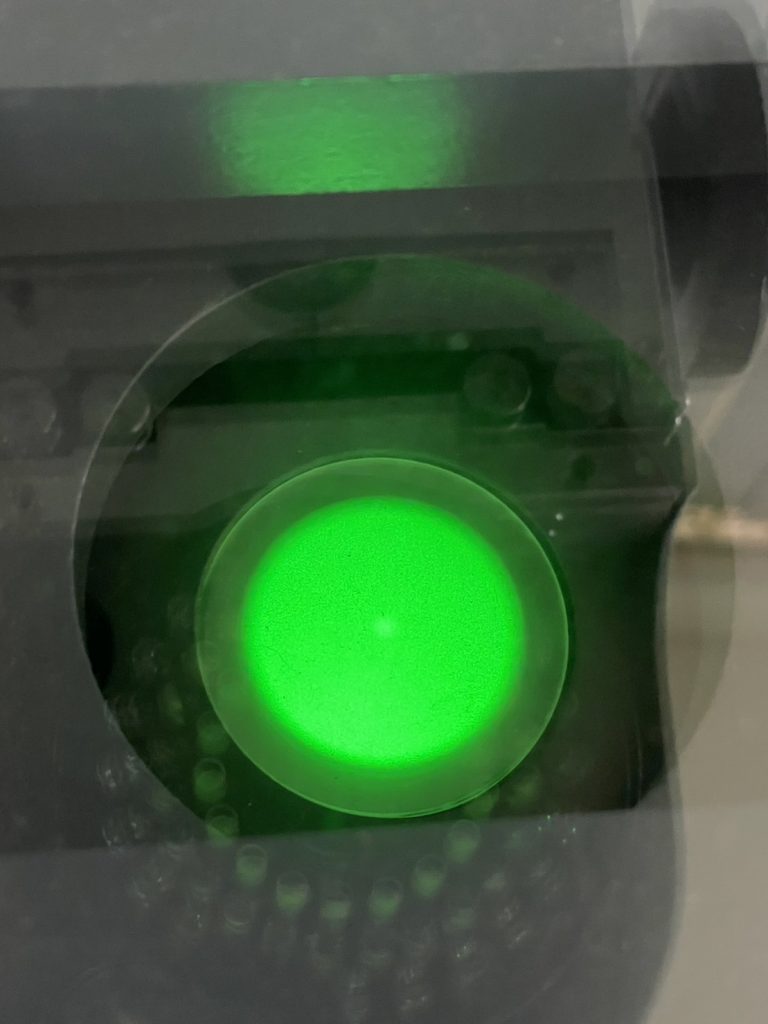

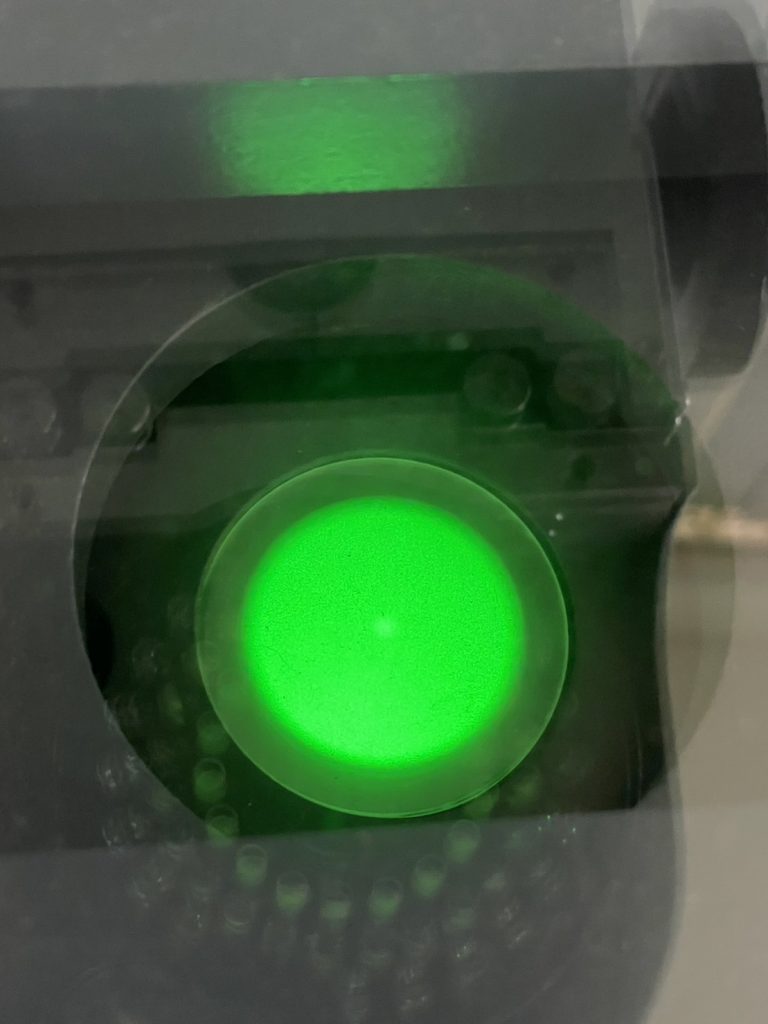

Standard light source system:

The upper light source is high-brightness LED ring light, and the lower light source is high-contrast telecentric light source green LED.

Machine control panel, intuitive operation brightness adjustment, machine and software connection lights

Optional:

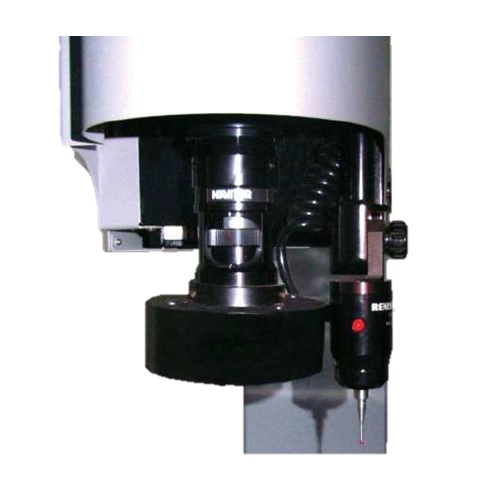

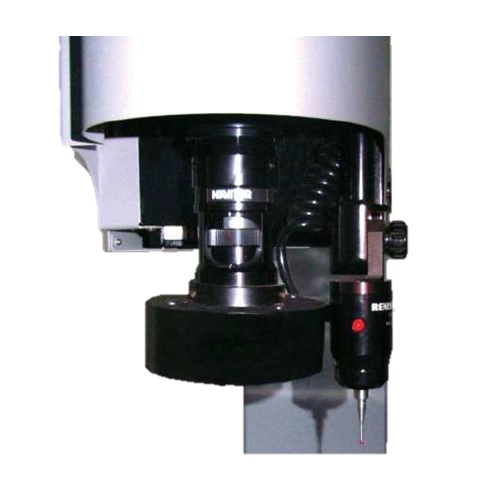

Simple probe measurement

Our company can also match optical lenses according to the client’s different magnification and light source requirements.

Diverse choices to accommodate different product measurements and meet customer expectations

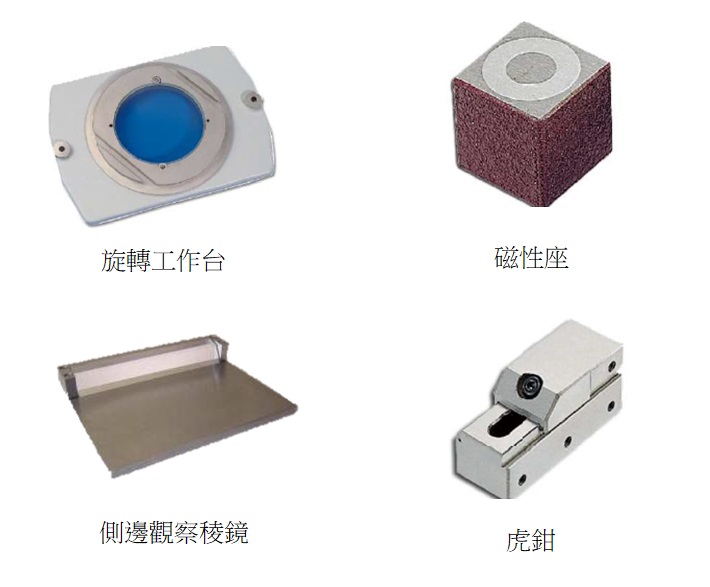

Optional:

Various optical lenses:

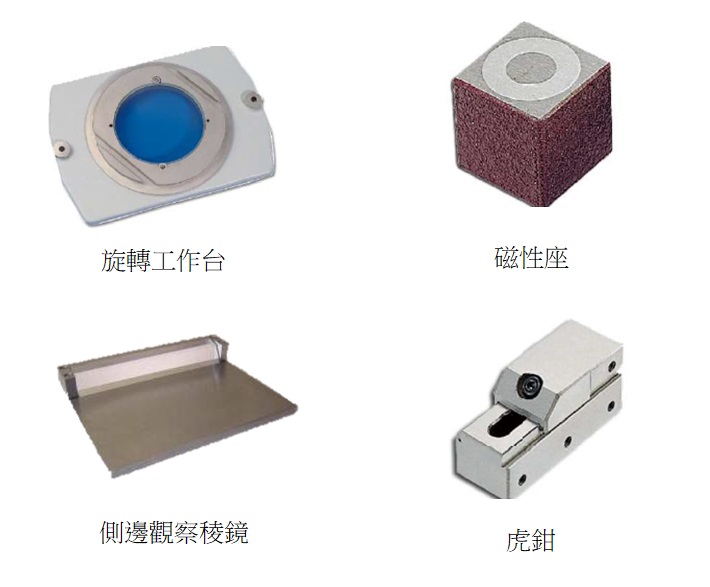

Other options:

※Welcome to email or call for consultation

Electronic feedback lens:

Optional feedback variable quilt lens;

When adjusting the magnification, the corresponding magnification of the software will switch accordingly.

Avoid turning the magnification measurement and forgetting to select the corresponding scale on the software

There will be no problem of measurement data errors

Software functions:

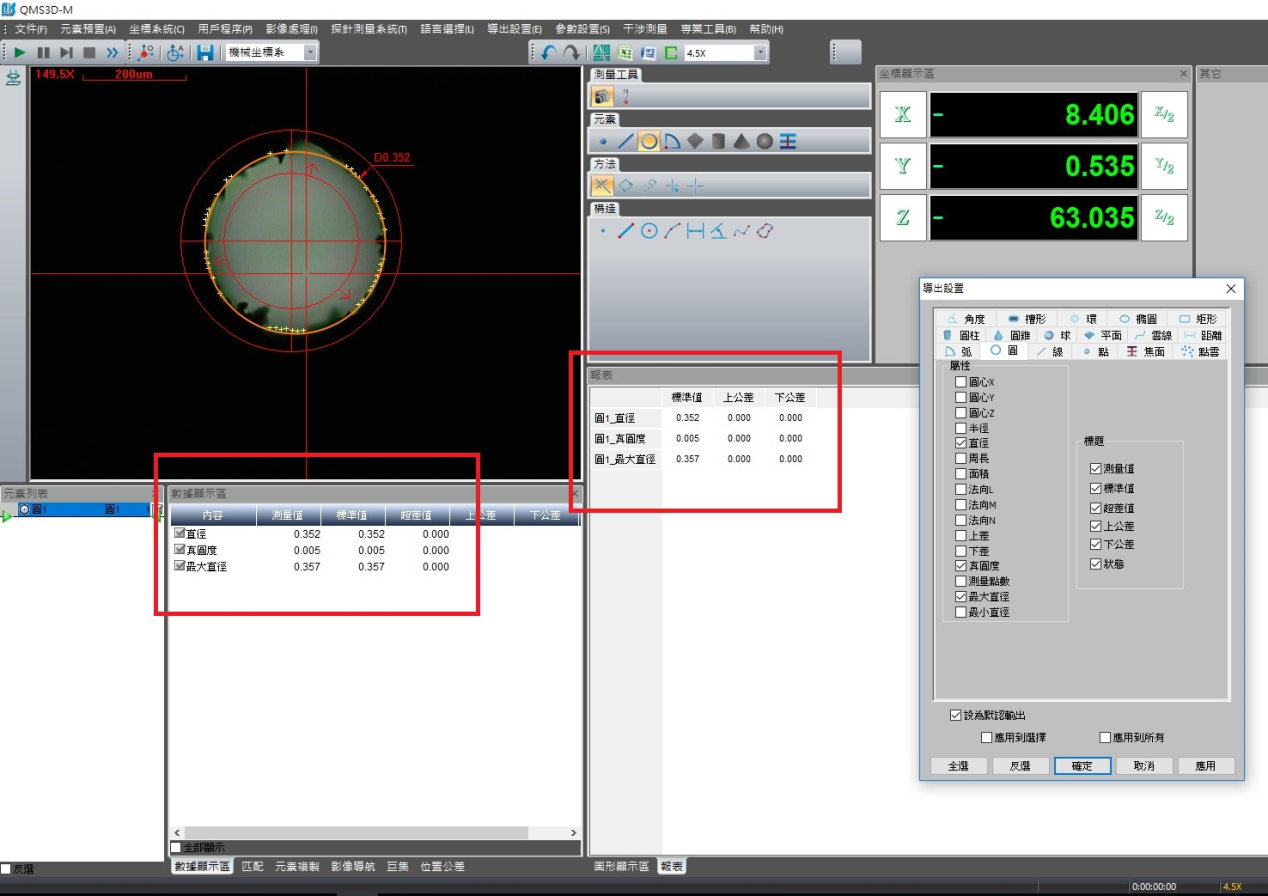

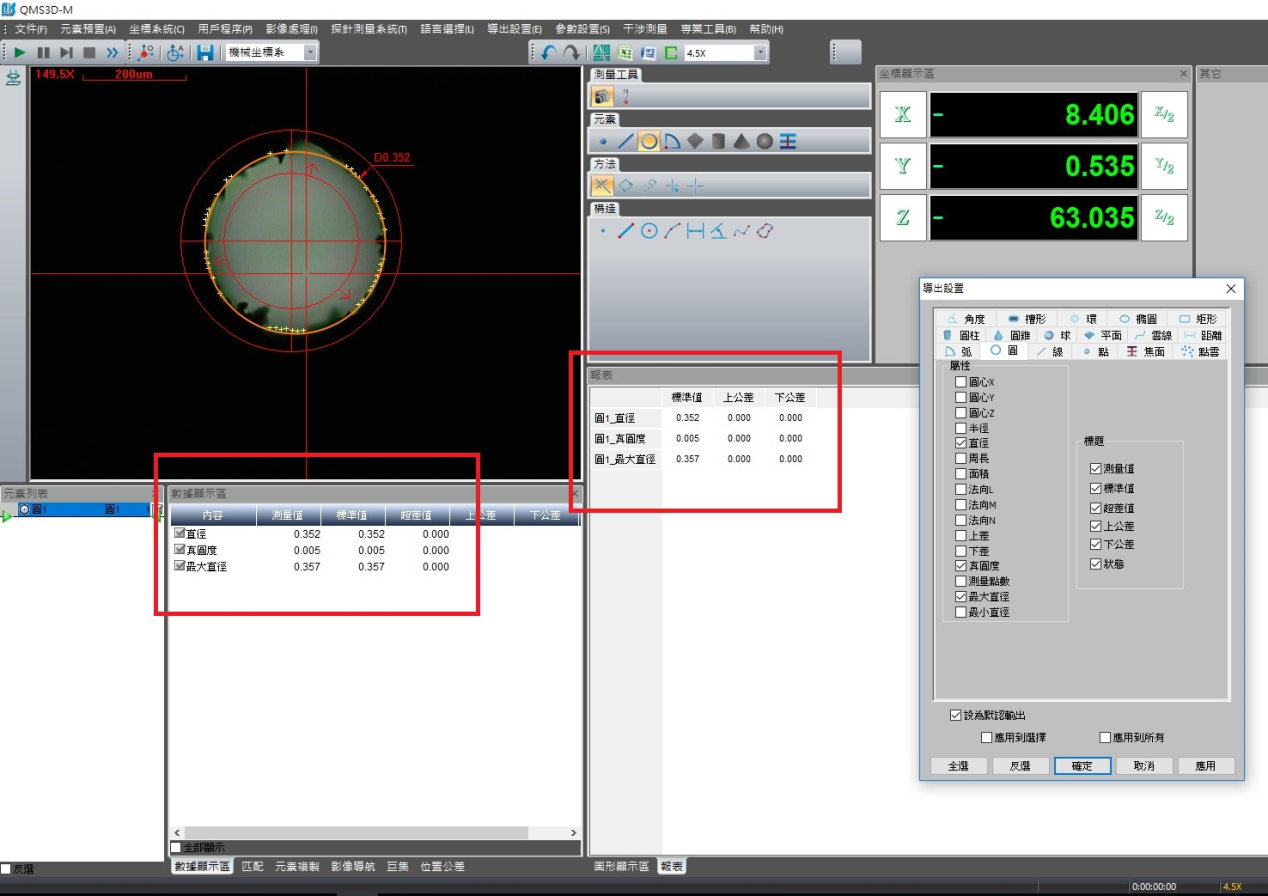

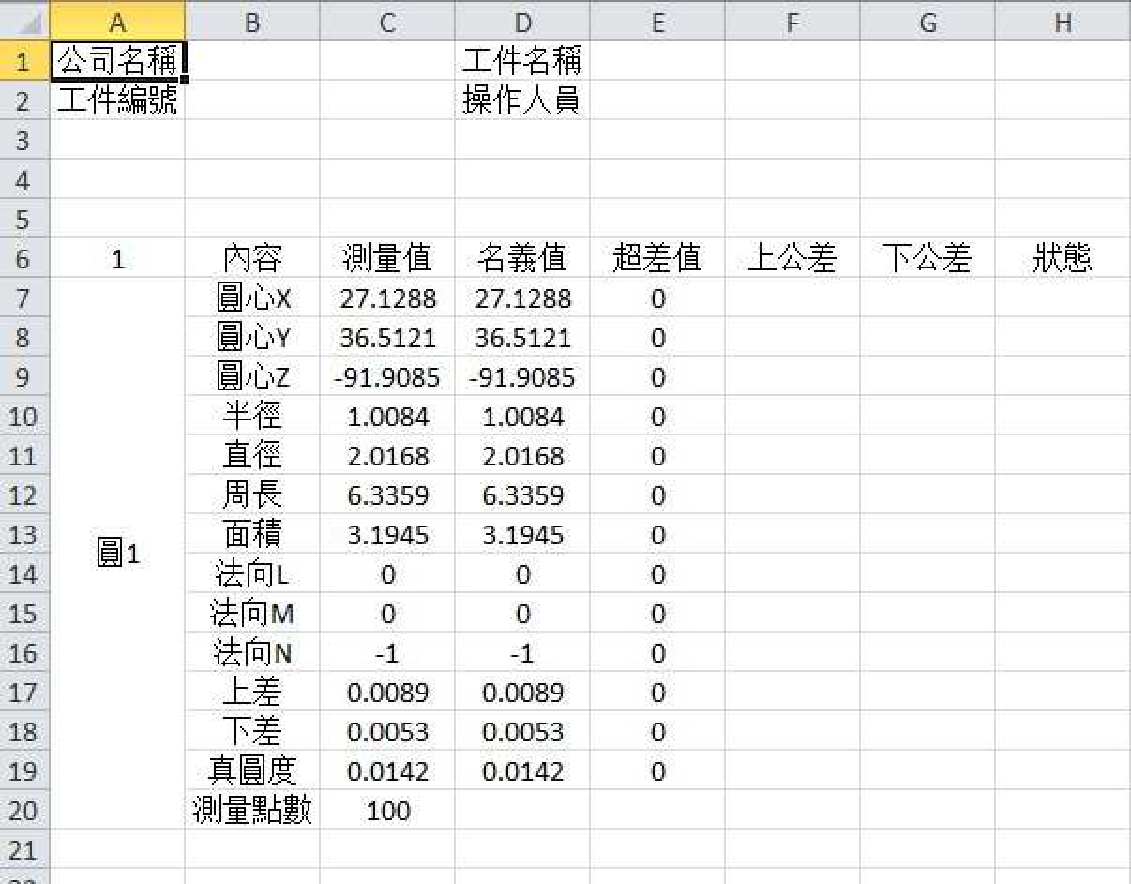

Geometric element measurement

Can measure fifteen kinds of geometric elements (point, straight line, plane, circle, arc, ellipse, rectangle, keyway, ring, cylinder, cone, sphere, open curve, closed curve and focal plane)

It can also measure height and preset basic geometric elements.

In addition, upper and lower tolerance limits can be set for the measurement data, and the software can determine whether to display PASS or NG after measurement.

It can measure across spans and perform combined measurements in the drawing area at the bottom right of the software. It can also be saved as a CAD file.

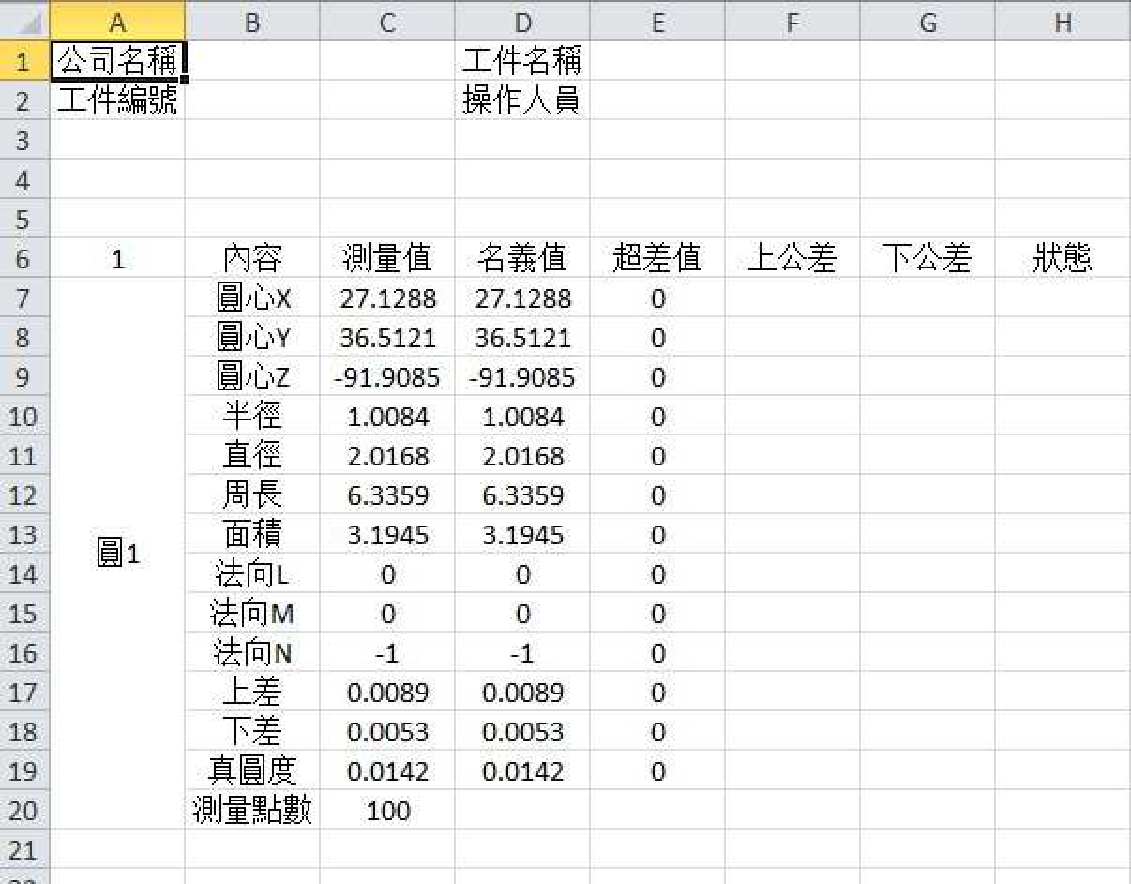

Multiple report export formats

You can set the exported content of elements, the export direction, and whether to export bitmaps.

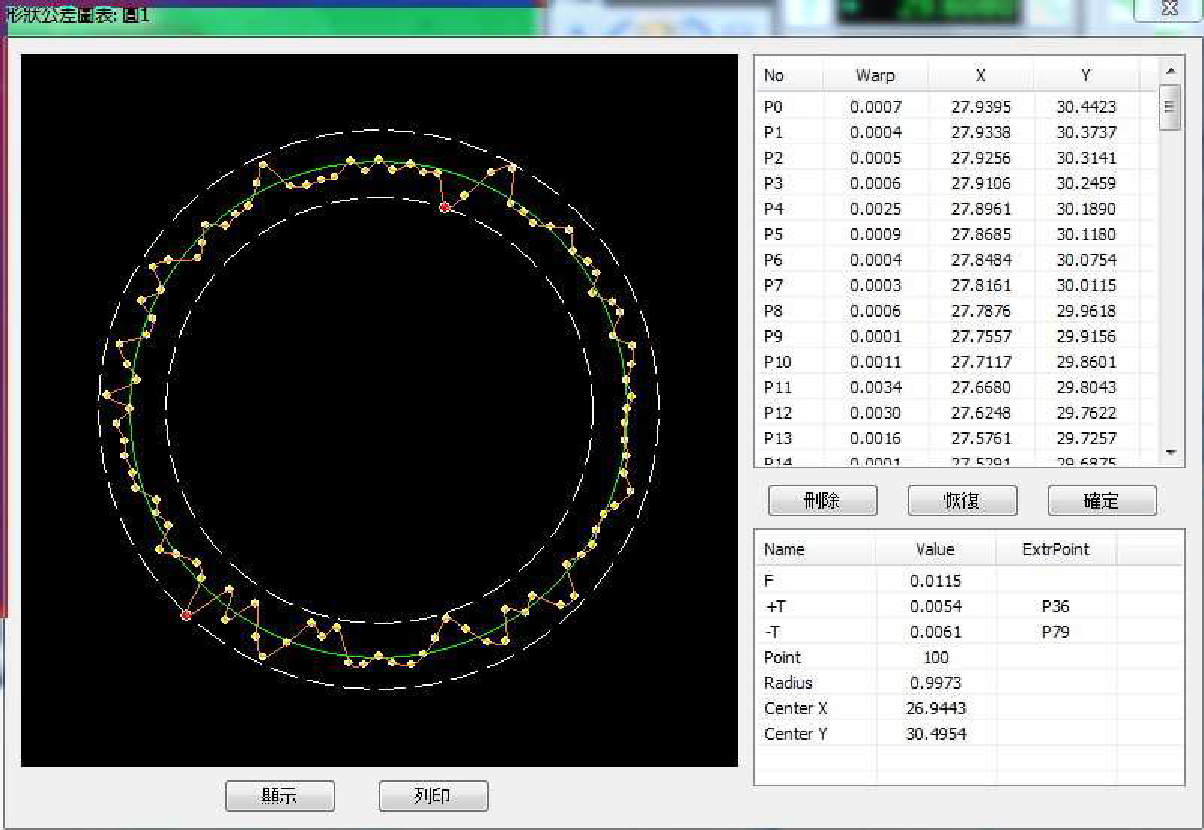

Geometric tolerance measurement

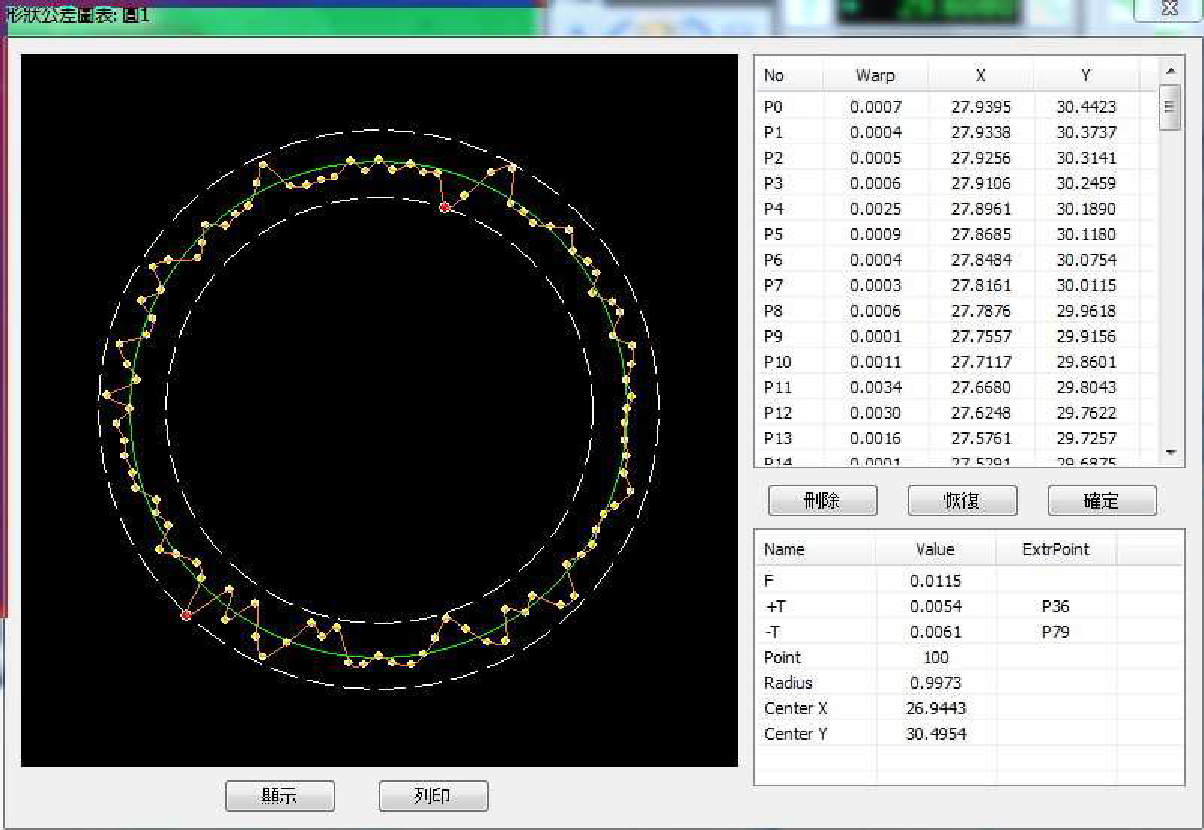

Shape Tolerance Chart:

Measure the shape tolerance charts of straight lines, circles, planes, cylinders, and balls. You can delete measurement point errors as needed.

If the difference is large, you can print the shape tolerance chart of the element and view the shape tolerance attributes.