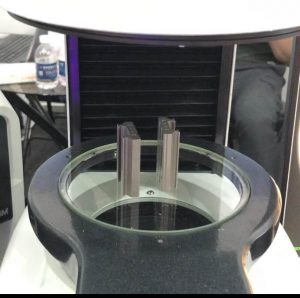

Dual lens magnification-FOV100mm, 50mm

Telecentric light source backlight, 15 degree 30 degree surface ring light independent control

Surface light can raise and lower the lighting distance

20 million pixel industrial camera

Fully electronically controlled lifting, automatic focus

Instantaneous inspection machine - video measurement

Facebook

twitter

Email

product description

Features

product specification

video introduction

Dimensional measurement and instant inspection machine

Instrument introduction:

- Dual lens magnification-FOV100mm, 50mm

- Telecentric light source backlight, 15 degree 30 degree surface ring light independent control

- Surface light can raise and lower the lighting distance

- 20 million pixel industrial camera

- Fully electronically controlled lifting, automatic focus

Measurement applications:

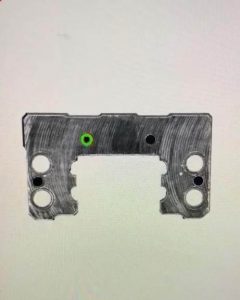

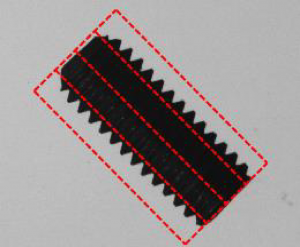

1. Measure 2D dimensions of large and small processed parts within the FOV

2. One-click measurement, all sizes, all workpieces

3. Industrial applications: sliders, fasteners, inductors, metal products

Workpiece measurement only needs to be set once and can be placed repeatedly to measure the full size.

Measurement ends in 1 second

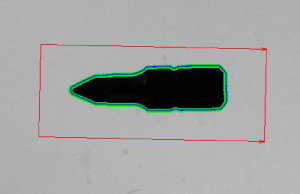

Surface features and surface blind holes can be measured

Use lighting system, 15 degrees 30 degrees, height setting

Adjust the best position and write the template

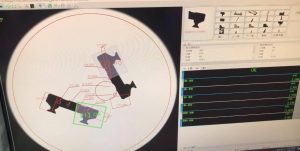

The workpiece does not need to be placed straight, it can be measured as it is placed

Observe measurement results

Just confirm OK or NG

Quick and easy operation

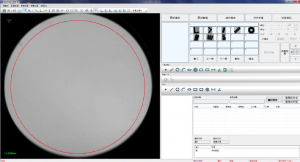

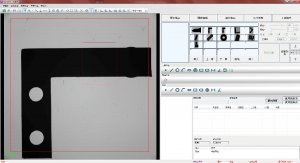

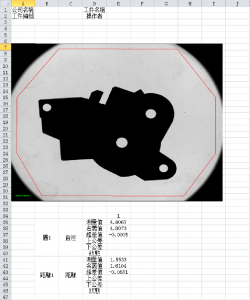

Software interface

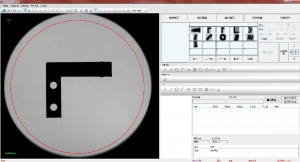

The overall interface of the software, pressing the switch mode will switch the interface

File creation interface↑

Measurement interface after switching↑

Saved file interface

File creation can record the file name and image

It is convenient to extract the file for measurement next time

![]()

Geometric measurement elements and edge-finding combined measurement functions

Special measurement functions:

Thread distance measurement

Point collection function

The software outlines the set of points

Dual lens magnification switching

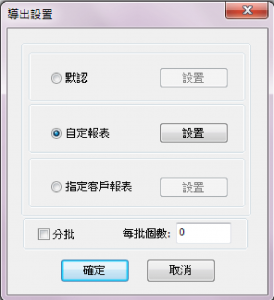

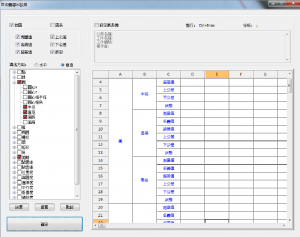

Program Usage-Report Export

You can choose to customize reports or use your own tables

Additional fields can be specified for output

In addition, you can also specify whether the data is arranged horizontally or vertically.

| Equipment Specifications: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||